TRUCK SERVICE MANUAL

ENGINE

wear; discard if damaged or worn smaller than 0.

inch

PARTS REPLACEMENT AND REPAIR

[2.11 mm]. New dimensions are 0.093 to 0.098 inch [2.36 to

Gear Cover Trunnion

2.49 mm].

If gear trunnion on cover is to be "bushed," install as follows:

Gear

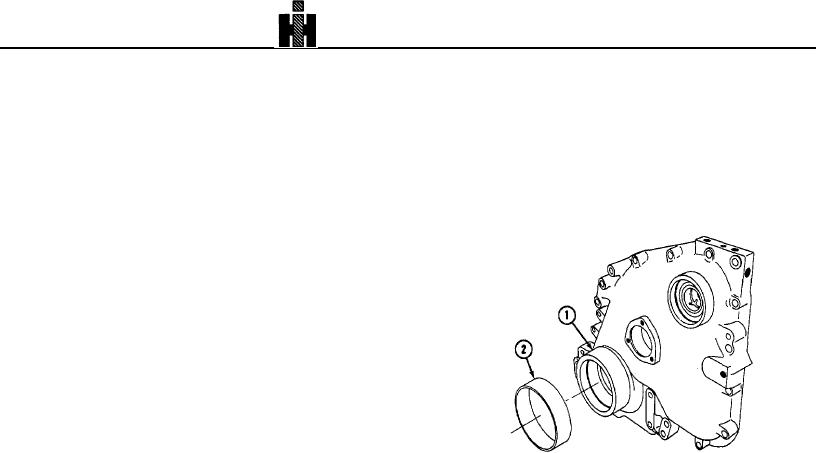

a. On 855 C.I.D. engines machine gear case trunnion (1

1. Remove gear if chipped, cracked or visibly worn. Gear

Fig. 1-12) to 4.747 to 4.750 inch [120.57 to 120.65 mm] outer

is press-fit on camshaft.

diameter.

2. Place camshaft in a press between V-blocks. Heat

gear with heating torch to 300 deg. to 400 deg. F [148 to 204

deg. C].

CAUTION

Never support gear on outer gear surface. Always

support hub area with V-blocks or equivalent spacers.

3. Press camshaft from gear; remove key.

4. Remove pipe plug from drive end of camshaft; clean

oil passages as required.

Note: On engines not equipped with outboard bearing,

camshaft contains an orifice plug 68193.

Do not mix with

other 1/8 inch orifice plugs.

5. Install pipe plug in drive end of camshaft, if removed.

Torque pipe plug to 5 to 10 ft-lbs [0.7 to 1.4 kg m].

6. Heat camshaft gear evenly to 400 deg. F [204 deg. C]

1. Gear Case Trunion

with heating torch. Maximum clearance between camshaft

2. Bushing

flange and gear face is 0.0015 inch [0.038 mm]; check with

Fig. 1-12. (N10145). Gear case cover and trunion bushing.

feeler gauge.

7. Place camshaft in press; insert new key in camshaft.

b. Press bushing (2) (Part No. 68226-1) over machined

Press on camshaft gear while hot.

trunnion with chamfered side of bushing toward gear case.

Note: Always check timing when a new camshaft or gear is

installed in an engine.

Camshaft Support

1. Front camshaft supports are used in gear cover of

GEAR COVER

some turbocharged engines and are one piece aluminum.

2. Check inside diameter, per wear limits in Table 1-1

INSPECTION

(15), discard unserviceable parts.

1. Remove and discard all oil seals.

Accessory Drive Bore Bushing (855 C. .D.)

2. Check trunnion and/or bushing for wear; replaceable

1. Check bore of accessory (fuel pump and compressor)

bushing is available to "rebuild" outside diameter of trunnion

drive; if worn larger than 1.571 inch [39.90 mm], replace.

which was not originally equipped with bushing.

2. If accessory drive shaft is worn enough to allow use of

3. Check thrust plates for deep scores or wear beyond

oversize bore bushing (maintain minimum clearance of 0.003

point where removal of gaskets will now allow establishment of

inch [0.08 mm] between shaft and bushing), use as listed in

correct camshaft end play. See Camshaft Installation, Group

Table 1-1 (16).

14.

3. Press in new bushing using ST-598 Mandrel.

342