TRUCK SERVICE MANUAL

ENGINE

Note:

Ampere-turns is defined as the amperage flowing

Viscous Dampers

through the coil, multiplied by the number of turns in the coil.

Viscous dampers operate on a different principle and are not

Most coils contain four turns and therefore only 700 amperes

as critical in their operation. Due to design, operation over a

need to be applied with DC equipment, or 850 amperes with

greater variation in load and mass is possible

AC equipment.

1. Spray damper with Spotcheck Developer, Type SKD-

c. Apply one and one-half percent wet solution while

NF, or equivalent. Place damper in oven heated to 200 deg.

current is on. Make visual inspection after each application of

F [93 deg. C]. Allow damper to reach oven temperature.

current.

2. Remove damper from oven and inspect for oil

2. Assemble cap to rod and alternately tighten nuts to

smudges or fluid leakage. If oil smudges appear, discard

operating tension as described in Table 1-1 (19).

vibration damper.

3. Check crankpin bore with a dial bore gauge or inside

3. Check damper for eccentricity and wobble after

installation. Refer to Group 14. An alternate but less effective

method for inspecting viscous dampers is by shaking damper.

a. On 2 bolt connecting rods the bore diameter must be

Movement of loose pieces may be felt or heard if fluid has

within 3.2722 to 3.2736 inch [83.114 to 83.149 mm] up to 30

been lost. Tap front face at outside and inside seal. If seal is

deg. on either side of parting line. Fig. 1-8.

broken, a hollow sound will be heard at break. The viscous

damper cannot be balanced in the Field; if out of balance is

suspected, install a new damper.

Vibration Damper Mounting Flange

1. Check damper mounting capscrew hole threads.

2. Maximum eccentricity of mounting flange, measured

on outside diameter of pilot, should not exceed 0.004 inch

[0.10 mm] total indicator reading. Wobble of flange, measured

at 2-3/4 inch [69.85 mm] radius, should not exceed 0.003 inch

[0.08 mm]. The above readings are to be taken after

assembly to engine. Crankshaft must be kept to front or rear

thrust limit while wobble is checked.

CONNECTING RODS

INSPECTION

1. Magnaflux all connecting rods, caps and bolts; discard

if cracks are detected.

Note: Be sure rod and cap are kept mated at all times.

a. Check rods for cracks with 1800 ampere current AC

equipment or 1500 ampere current DC or rectified AC

equipment longitudinally between plates.

b. Check rods for cracks with 3000 to 3400 ampere-turns

with AC equipment or 2600 to 2800 ampere-turns with DC or

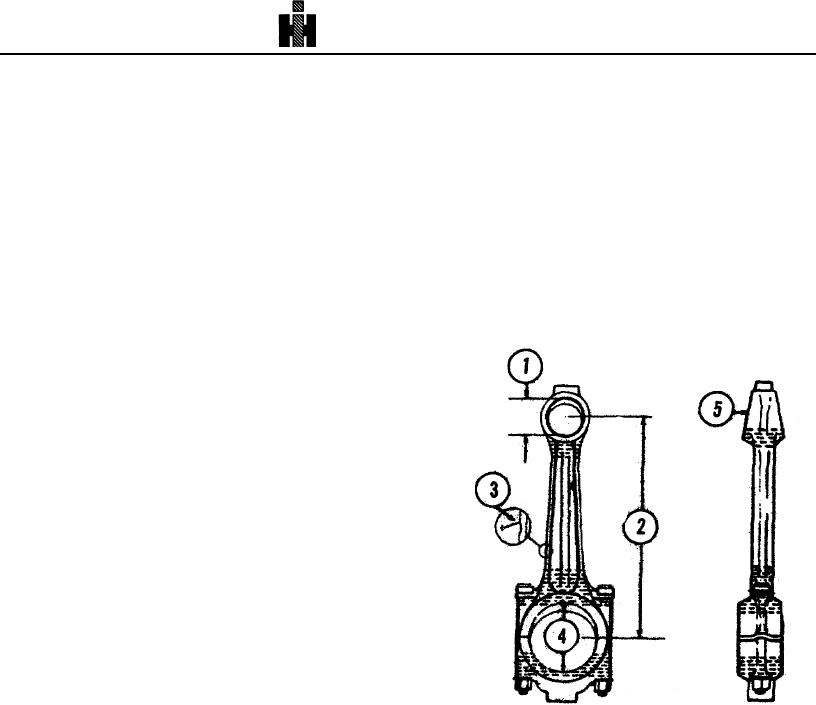

1.

Pin Bushing Bore

rectified AC equipment in a coil. Pay particular attention to

2.

Rod Length

shaded critical areas shown in Fig. 1-6.

3.

Defect In Rod

4.

Crankpin Bore

5.

Rod Taper

Fig. 1-6 (V40114). Connecting rod specifications.

337