TRUCK SERVICE MANUAL

ENGINE

5. Lift rod, arbor and pin assembly from fixture; turn

horizontally 180 deg; set back in fixture. Readjust dial

indicators to divide difference between first and second

readings; fixture is now calibrated.

Check Rod Alignment

1. Measurements read directly from dial indicator indicate

comparative

length

and

misalignment

of

bores.

Measurements apply with or without bushing installed.

2. Assemble ST-563 Mandrel Set in rod to be checked.

Set rod in fixture; be sure pin in mandrel is down and locked in

position in center line of rod.

3. Take readings for length (compared to length set up in

calibration of fixture) and misalignment of bores (difference

in reading from one indicator to other).

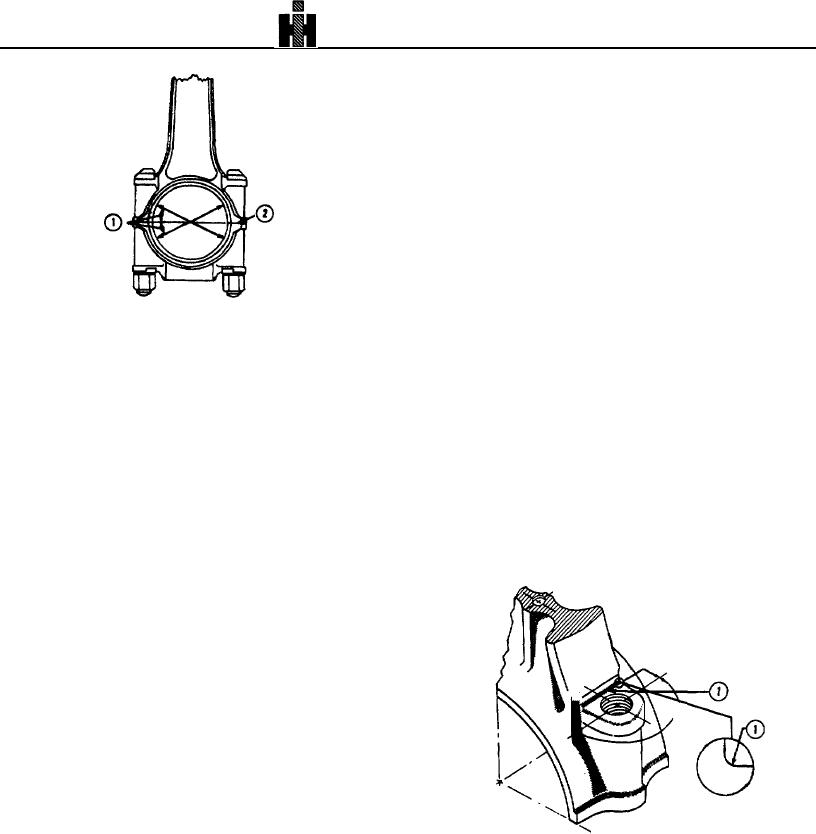

2. Parting Line

4. Turn rod 180 deg. Total reading must not exceed

Fig. 1-8 (N10194) . Connecting rod wear limits

0.008 inch [0.20 mm] when connecting rod does not contain

bushing or 0.004 inch [0.10 mm] with bushing installed and

bored to size. This is combined plus and minus readings of

b. On 2 bolt connecting rods, bore diameter must be

indicator. Length must read 0.001 inch [0.03 mm] on gauges.

within 3.2722 to 3.2732 inch [83.114 to 83.139 mm] beyond 30

deg. on either side of parting line.

5. Measure rod twist with a feeler gauge between piston

pin and dial holding plate. When measuring connecting rod

twist in ST-561 and rod does not contain piston pin bushing,

c. If either specification is not met, the rod must be

twist must not exceed 0.020 inch [0.51 mm]. Twist must not

resized.

exceed 0. inch [0.25 mm] with bushing in place and bored to

4. Gauge piston pin bushing diameter with ST-205 Plug

size.

Gauge or with inside micrometer. See Table 1-1 (11).

Check Bolts, Bolt Holes And Bolt Pads (2 Bolt Rod)

5. Use ST-561 Checking Fixture and ST-563 Locating

1. The bolt head must rest squarely on milled surfaces of

Mandrel to check rod alignment.

rod.

2. If connecting rod bolts have been tightened

Calibrate ST-561 Checking Fixture For Rod Size

excessively

1. Select a new rod that has been checked for correct

absolute center to center length, 12 inch [304.80 mm] between

centers. Production rods may vary from 11.998 to 12.000 inch

[304.75 to 304.80 mm] .

2. Assemble cap to rod as described in Step 2 under

Inspection.

3. Insert piston pin, furnished in ST-563 Mandrel Set, in

piston pin bore. Insert and tighten ("snug" only) expanding

arbor in crankpin bore.

CAUTION

The expanding arbor must be installed with locking

pin down and on center line of rod.

4. Set rod in fixture and move dial holder so dials

indicate on piston pin. Zero dial indicators.

1. Bolt Head Fillet Radius

Fig. 1-9 (N40114A) Connecting rod radius specifications.

338