TRUCK SERVICE MANUAL

ENGINE

2. Total worn maximum oil clearance should not vary

more than 0.002 inch [0.05 mm] between adjacent main

bearings. See Table 1-1 (7-8).

Note: Under no circumstances should an attempt be made to

scrape bearing shells, nor should they be lapped or filed to

increase oil clearances. A properly fitted bearing will appear

dull gray after a reasonable period of service, indicating it is

running on an oil film. Bright spots indicate metal-to-metal

contact and black spots indicate excessive clearance.

CRANKSHAFT THRUST RINGS

1. The best measurement of wear on crankshaft thrust

rings is the crankshaft end clearance check. See "Engine

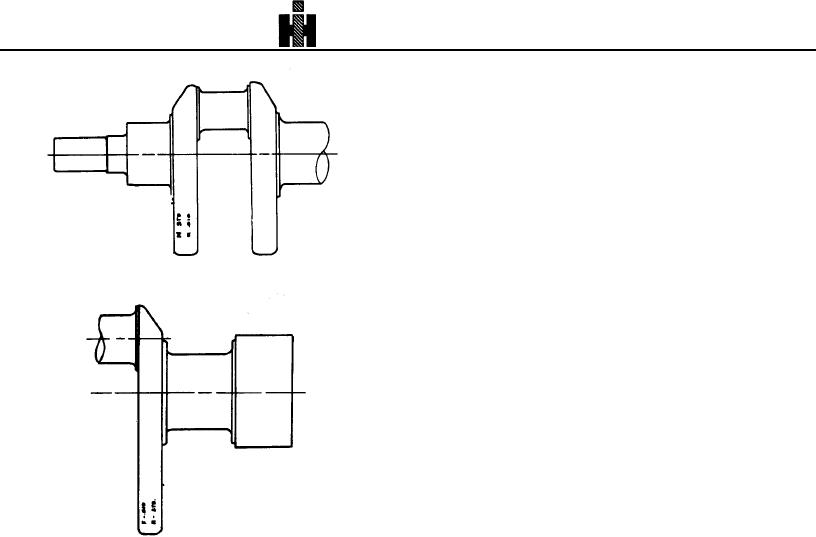

Fig .

143 (V50138) Identification of rod and main journal size

Assembly" Group 14 and Table 1-1 (9-10).

2. Oversize thrust rings are available; be sure to use

same size (thickness) half-ring on both upper and lower

portions. Stamp crankshaft rear counterweight indicating size

used.

Note: Allowable amount of wear on thrust ring depends upon

wear of crankshaft surfaces. Installed in a cylinder block,

crankshaft end clearance should not exceed 0.022 inch [0,56

mm] at rebuild; however, at the maintenance check, when

engine is operating satisfactorily, end clearance is allowable to

maximum of 0.035 inch [0.89 mm on 855 series engines.

VIBRATION DAMPER

The vibration damper is a unit which counteracts twisting or

torsional vibrations of crankshaft. The damper is engineered

to match engine model on which it is used. To prevent failures

make sure it is operative at all times. Two types of vibration

Fig .

1-4 .

(N101140) Oversize thrust bearing mark on

dampers are used on Cummins engines rubber element and

crankshaft

viscous.

CLEANING

c . Lubricate flange with high pressure grease and drive

Viscous dampers should be cleaned of rust, dirt or grease

gear onto shaft with piece of tubing.

with a suitable solvent cleaner.

d. Install lockplate and nut (if used).

Dampers are not subject to Field repair; therefore, if inspection

shows them to be defective, install new dampers.

BEARINGS

Rubber Element Damper

Main and connecting rod bearings (or shells) are two-piece

Most engines use rubber element dampers, which are tuned to

units with one unit containing an oil hole for lubrication. Thrust

the engine's natural system frequency. These are made of

rings are used at the rear main bearing.

metal units separated by rubber compound material. The

dampers are designed to provide adequate protection for

INSPECT BEARING SHELLS

1. Gauge shell with ball point micrometer, dial indicator

thickness gauge, or comparator. Discard shells that are worn

more than 0.001 inch [0.03 mm] or if chipped, flaked, or

scored. See Table 1-1 (7-8) for thickness of standard shells.

336