TRUCK SERVICE MANUAL

ENGINE

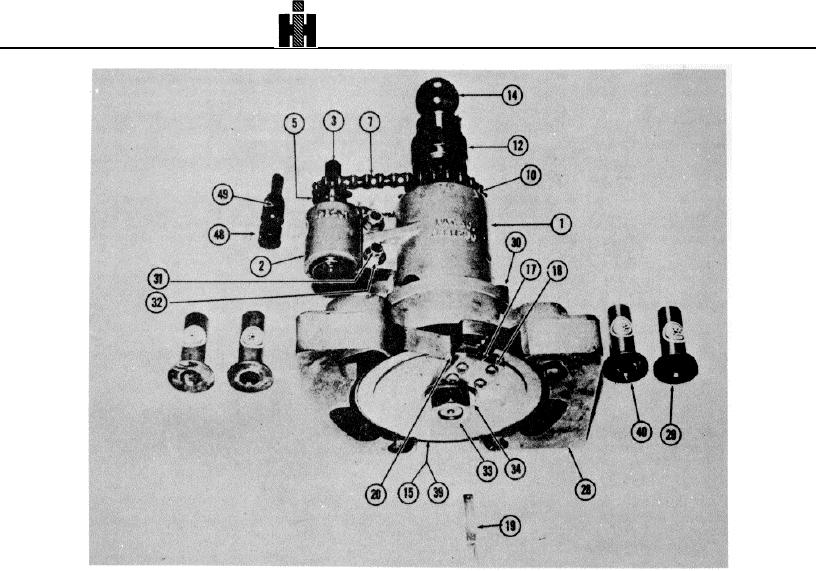

1.

Body

12.

Depth Collar

20.

Adjusting Pin

33.

Jam Nut

2.

Drive Bracket

14.

Knob

28.

Base Plate

34.

Washer

3.

Drive Shaft

15.

Guide Plate

29.

Spacer

39.

Guide Plate

5.

Drive Sprocket

17.

Tool Locating Plate

30.

Capscrew

40.

Adapter

7.

Drive Chain

18.

Capscrews

31.

Bolt

48.

Universal Joint

10.

Driven Sprocket

19.

Tool Bit

32.

Nut

49.

Roll Pin

Fig. 1-15, (V40172). ST-1168 Boring Tool.

pulling up on retractor knob while pushing down on set collar.

15. With drill on half inch drive of boring tool (ST-1168-3),

bore hole until drill freewheels. About half way down during

13. Loosen set collar setscrew and back off collar

cut, tool bit begins cutting out old counterbore ledge, operator

counterclockwise until salvage sleeve can be placed between

should have a firm grip on drill to be prepared for increased

collar and boring machine main body as a depth indicator.

load on drill from added metal being cut. Stop immediately

Tighten setscrew in set collar. Remove feeler gauge.

when drill freewheels.

Note: This spaces the set collar to cut a depth 0.

inch

16. Retract tool holder by pulling up on retractor knob.

[0.10 mm] less than total height of salvage sleeve to be used.

Remove tool bit from tool holder. Clean away all shavings and

14. Place 1/2 inch drive flex adapter (ST-1168-48) in a 1/2

deburr bore with emery cloth.

or 3/4 inch heavy duty (10 amperes or more) hand drill.

CAUTION

INSTALLING SALVAGE SLEEVE

Do not use drill rated less than 10 amperes or over

1. Clean bore thoroughly with a nonpetroleum base

450 rpm.

solvent or cleaner.

346