TRUCK SERVICE MANUAL

ENGINE

6. The cleaner requires 'no separate gaskets for seals;

AIR CLEANERS AND PIPING

therefore, care must be taken when inserting cartridge to

Dry Type Servicing

insure a proper seat within air cleaner housing. Firmly

1.

Disassemble cleaner.

Clean element

with

press all edges and corners of cartridge with fingers to

compressed air.

effect a positive air seal against sealing flange of

2. Wipe out housing with clean cloth.

housing. Under no circumstances should cartridge be

3. Inspect gasket, replace if not reusable.

pounded or pressed in center to effect a seal.

4. Install new or cleaned element.

5. Assemble cleaner.

7. Assemble cleaner.

Heavy Duty Single And Dual Type Servicing

CLEANER RESTRICTION INDICATOR

1. Wipe dirt from cover and upper portion of cleaner.

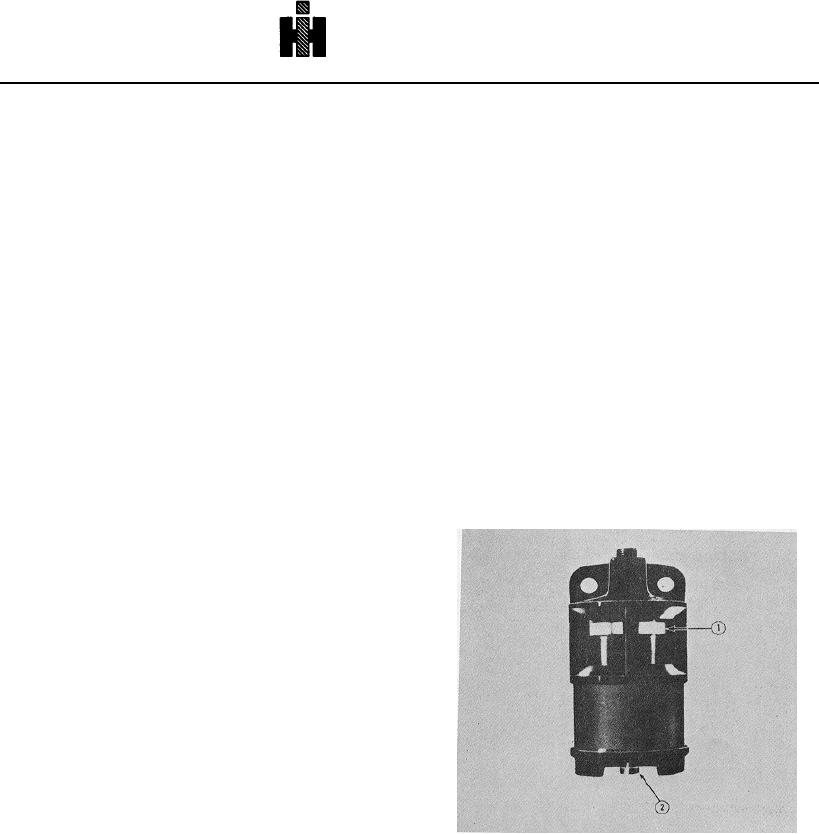

1. The restriction indicator signals when to change

2. Disassemble cleaner and remove element.

cartridges. The red flag (1, Fig. 10-2) in window

3.

Blow out element from clean air side using

gradually rises as cartridge loads with dirt. Do not

compressed air of not more than 100 psi [7 kg/sq cm].

change cartridge until flag reaches top and locks in

4. Wash element with non-sudsing detergent and warm

position. When locked, flag will remain up after engine is

water. Dry with compressed air not exceeding 40 psi [2.8

shut down. After changing cartridge, reset indicator by

kg/sq cm].

pushing re-set button (2). Push button all the way in

5. Inspect element for holes.

firmly; then release. If button sticks, repeat pushing

6. Install new or cleaned element.

slowly.

7. Check air restriction indicator, if air restriction is

2. A second method is utilization of a vacuum gauge and

excessive, disassemble air cleaner, remove wing nut and

warning light that performs the same function as

replace safety element.

described in Step 1. Components for vacuum gauge

8. Reassemble air cleaner.

include electrical source (1, Fig. 10-3) air piping (2),

vacuum switch (3) and red warning light (4).

Cartridge Type Air Cleaner Servicing

1. Disassemble cleaner. Remove dirty Pamic cartridge

by inserting fingers in cartridge opening. Loosen all four

corners, one at a time by pulling straight out.

2. Clean pre-cleaner or moisture eliminator (where

applicable). Wipe out housing with clean cloth.

3. Inspect housing and all other parts. Replace if

defective.

4. It is not recommended to clean and reuse cartridge.

5. Install a new cartridge; hold cartridge in same manner

as when removing from housing. Insert clean cartridge

into housing; avoid hitting cartridge tubes against sealing

flange on edges of air cleaner housing.

1. Red Flag

2. Re-set Button

Fig. 10-2, (CGS-20). Air cleaner restriction indicator

389