TRUCK SERVICE MANUAL

FUEL SYSTEM

Check 1 - Master Injector

Correction

This can be substantiated or disproved by calibrating a

set of injectors at 132 cc and engine testing them. If the

Cause

fuel rate vs. manifold pressure relationship is not within

specifications, a miscalibrated master injector is verified.

Master injector out of calibration.

During this check the utmost accuracy is required in

weighing the fuel and recording the manifold pressure.

Check 2 - Test Oil Temperature

The correct camshaft and pistons as listed on the CPL

must be used during this test.

Cause

Replace the faulty master with a new master ordered

from the Factory. Clean and correct the faulty master,

Test oil at excessively high or low temperature.

and use it in an engine. Never use an injector as a

master after it has been taken apart or changed in any

way.

Correction

Setting up test stand or calibrating injectors while test oil

is at excessively low or excessively high temperatures.

Check test oil temperature indicator against master

thermometer and compensate as necessary for any

existing differential. It may be necessary to connect cold

or hot water lines to heat exchanger at back of tank to

maintain test oil temperature at the required 90 deg. to

95 deg. F [32 to 35 deg. C]. If temperature exceeds 95

deg. F [35 deg. C] increase cold water flow. If

temperature exceeds135 deg. F[57 deg. C] drain and

replace with new test oil.

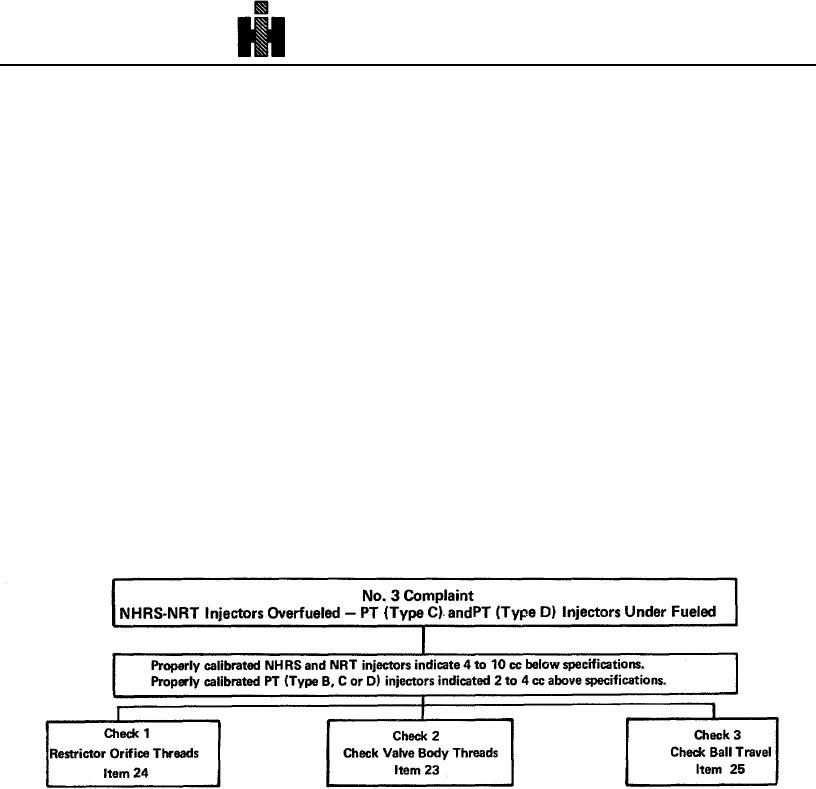

Check 1 - Restrictor Orifice Threads

Correction

Torque resistor orifice into check-valve body at 6 inch-lbs

[.7 N. m].

Cause

Correction

Leakage around restrictor orifice threads.

Use gasket (0.030 inch [.76 mm] throttle adjusting shim)

Check 2 - Check Valve Body Threads

under check-valve body. Torque check-valve body into

cup seat block at 10 to 12 inch-lbs [1.1 to 1.4 N. m}.

Cause

Leakage around check-valve body threads.

489