TRUCK SERVICE MANUAL

FUEL SYSTEM

Check 1 - Drain Flow Lines

Correction

Replace per line K in Fig. 6-1-121.

Cause

Use of a line with less than 5/16 inch [7.95 mm] I.D. or

crimp caused by sharp bend in drain line.

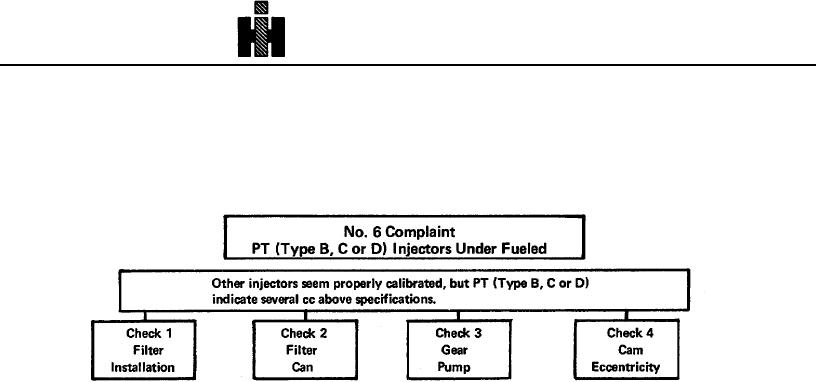

Check 1 - Filter Installation

Correction

Install filter.

Cause

Filter assembly must be in specified location as shown.

Removal of the filter assembly from the circuit.

Correction

Installation of the filter assembly in the suction side of the

gear pump.

Filter must be of specified type.

Check 2 - Filter Can

Correction

Cause

With the pressure regulator by-pass line (line G, in Fig.

6-1-121) completely blocked, check the gear pump

Installation of a smaller or more rigid than standard filter

against a 0.045 inch [11.1 43 mm] orifice installed in line

can.

L.

The gear pump is acceptable if it delivers 80 to 120 psi

Check 3 - Gear Pump

[552 to 827 kPal during this check.

If the gear pump delivers less than 80 psi [552 kPa],

Cause

check the fuel strainer for clogging end consequent

pump suction restriction and clean if necessary; the gear

Low gear pump delivery.

pump must be replaced.

Check 4 - Cam Eccentricity

Correction

Cause

Check as follows:

Cam base circle eccentricity.

(a) Align timing wheel mark and pointer.

(b) Install ST-790-5111 load cell with regulated air

pressure to give 380 lbs. [172 kg] load. Repeat the

clamping several times to assure that the setting of the

clamping load is correct.

491