TRUCK SERVICE MANUAL

FUEL SYSTEM

Check 8 - Air Pressure Regulator

Correction

Drain regulator bowl each day by releasing spring loaded

Cause

valve.

Excessive moisture.

Clean filter by removing bowl, wash in solvent and air

dry.

Regulated pressure "creeps."

Remove the top housing, valve seat and valve assembly.

Inspect the disc and seating surface of valve seat.

Check 9 - Hydraulic Clamping

Inspect the valve guide and valve guide recess for

Cause

foreign particles. Clean all parts thoroughly.

Leaks-(hydraulic clamping system).

While the top housing is removed for the preceding step,

This may be verified by the following check:

check the diaphragm and slip ring and replace faulty

parts.

(1) Clamp the load-cell in the stand.

(2) If after 3 minutes the load-cell reading should

Correction

change position by more than 20 lbs [9.07 kg].

(3) Dry all plumbing connections and watch for

(See below for specific corrections.)

seepage with

air valve closed and with it open.

Check for leaks at bleed plug and correct as required.

(4) If no external seepage is indicated and the

condition still

Correct as required.

persists, one of the following exists.

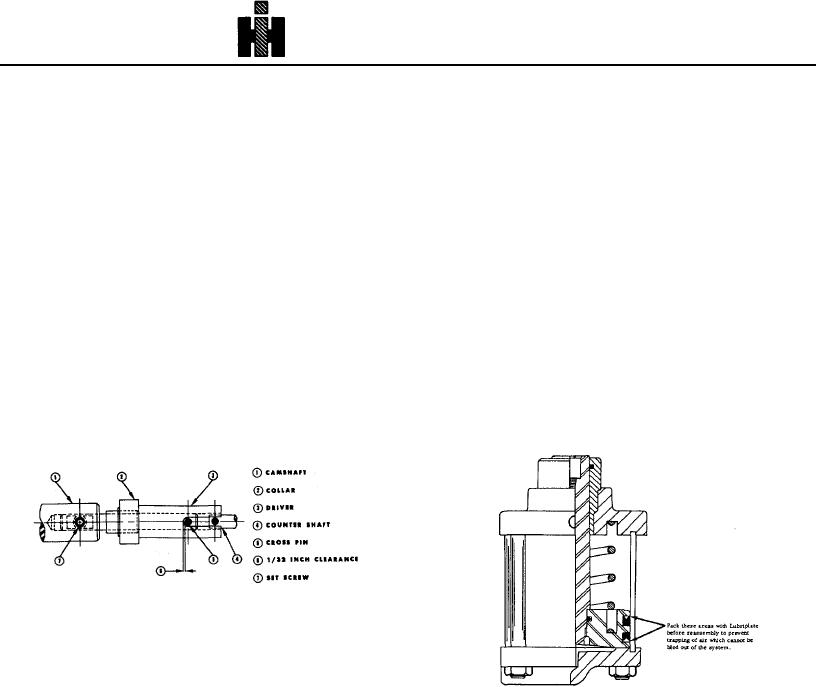

If 1/32 inch clearance has been affected because of loose set screw or

any other condition, the following steps should be taken to obtain

proper clearance.

1.

Loosen set screw so that shaft slides freely in housing.

2.

Manually engage clutch by fully depressing solenoid (inside

Fig. 6-1-123, F60159. Hydraulic loading cylinder

main housing). With clutch held in this position, the cross pin in the

clutch shaft should be positioned to clear the end of the "U" slot in

clutch driver by approximately 1/32 inch.

3.

Tighten set screw against flat on clutch shaft.

4.

Check operation, if solenoid is noisy (loud hum or chatter)

recheck Step No. 2.

Fig. 6-1-122, F601060. Position of collar and drive clutch

486