TRUCK SERVICE MANUAL

FUEL SYSTEM

Capscrews And Washers

Filter Screen Optional Replacements

Capscrews used in connecting a part to aluminum

Two new fuel filter screens, both with a 40 micron mesh

should have an engaging thread length two times the

rating, are available for use in the PT fuel pumps. Filter

diameter. Observance of this rule will prevent stripping

screen, Part No. 200004, is used to replace screen, Part

threads with a capscrew that is too short or breaking a

No. 146483, when additional protection is desired in

part from using a capscrew that is too long.

single screen type fuel pumps.

Lockwashers must never be used next to aluminum.

Use of the new screen also provides a good check on

Always use a flat washer between the lockwasher and

the primary fuel filter to see If the filter is performing its

aluminum part.

proper filtration functions. Tests with a good primary

filter indicated the 200004 Screen should be cleaned at

FUEL PUMP FILTER SCREEN

50,000 mile or 1600 hour intervals. However, when a

Cummins engines are equipped with single or double

questionable primary filter was used, the screen cleaning

fuel screens, located in fuel pump housing.

periods had to be moved up to much closer intervals to

prevent clogging.

Disassembly And Inspection

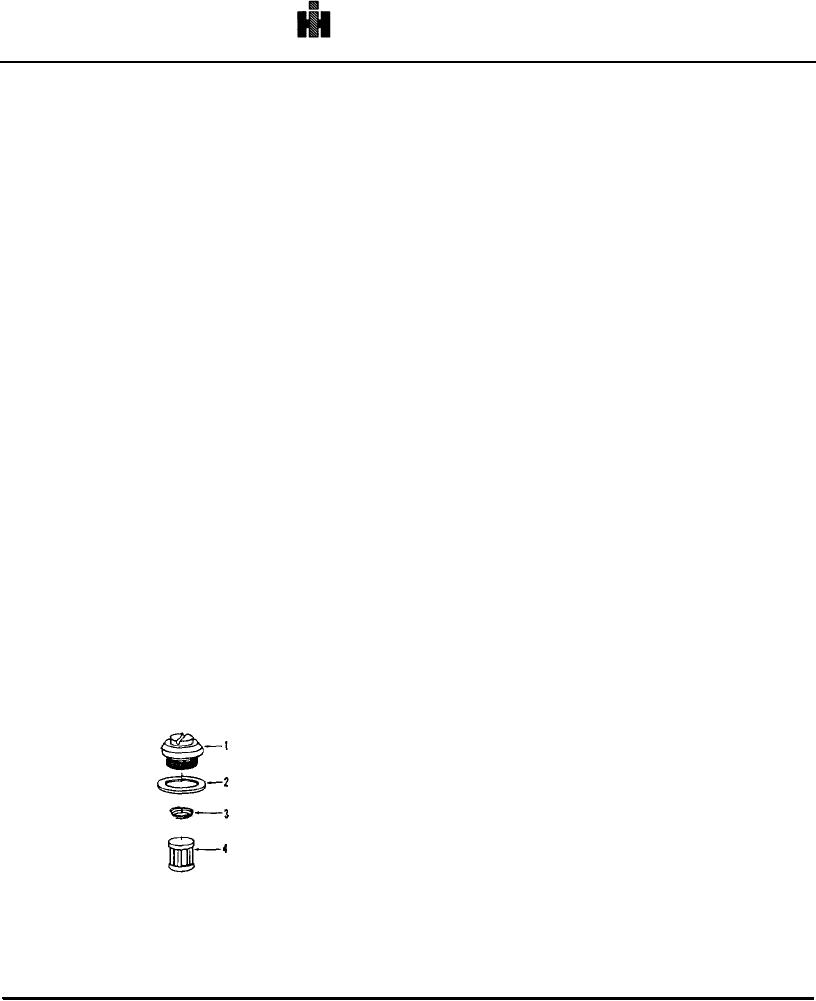

Two types of screens are used on PT Fuel Pumps.

FUEL PUMP HOUSING

1. The standard automotive screen assembly mounts in

The fuel pump housing is the largest part of the fuel

top of fuel pump housing. Fig. 5-16.

pump and contains the governor barrel, throttle shaft

a. Remove upper retainer, the top retainer contains a

The drive shaft bushing, throttle sleeve, governor barrel

magnet to pick up any iron particles that may have

and spring pack housing still remain in the fuel pump

entered the fuel pump. Some screens are one piece.

main housing.

b. The lower retainer and screen has hole In center to

permit fuel flow.

The drive shaft bushing and governor barrel can be

c. Clean retainer in fuel oil and blow dry with

removed if damaged. The throttle sleeve was honed to

compressed air. Visually inspect retainer and magnet for

size after assembly to the housing, and due to the close

damage or excessive wear.

tolerances must be returned to a Cummins Distributor for

d. Proper cleaning of the filter screens can best be

repair or replacement. Exchange housings are available

accomplished by soaking In a carbon-dissolving agent,

to reduce downtime to a minimum, as this is a

followed by flushing in a sonic cleaner unit, or clean the

specialized repair and only performed by Factory Repair

screen and retainer portion in fuel oil and dry with

Stations.

compressed air.

e. Visually Inspect screen for holes or imbedded metal

Drive Shaft Bushing

particles in mesh.

f. Discard damaged or worn parts and replace with

1. Check drive shaft bushing for sign of seizure or

new parts.

burrs.

2. Check drive shaft bushing 1.D. with inside

micrometers; If worn beyond 0.7525 Inch [19.11 mm]

replace bushing.

3. Remove worn bushing using a gouge chisel or half

Inch pipe tap, After tapping bushing, screw a half inch

pipe cap on a close nipple and screw the half inch nipple

into the bushing. Insert a punch through the rear of the

housing and drive out the bushing.

4. Apply a thin coat of high pressure lubricant to a new

front drive shaft bushing; press bushing into housing

flush with housing bore using an arbor press.

Fig. 5-16, F5183. Fuel filter screens

5. Line ream bushing to 0.7495 to 0.7505 inch [19.04 to

19.06 mm] with ST-490 Ream Fixture, and a well oiled

0.750 inch (3/4 inch [19.05 mm] ) reamer, Fig. 5-17.

Check bushing I.D.

499