TRUCK SERVICE MANAUL

FUEL SYSTEM

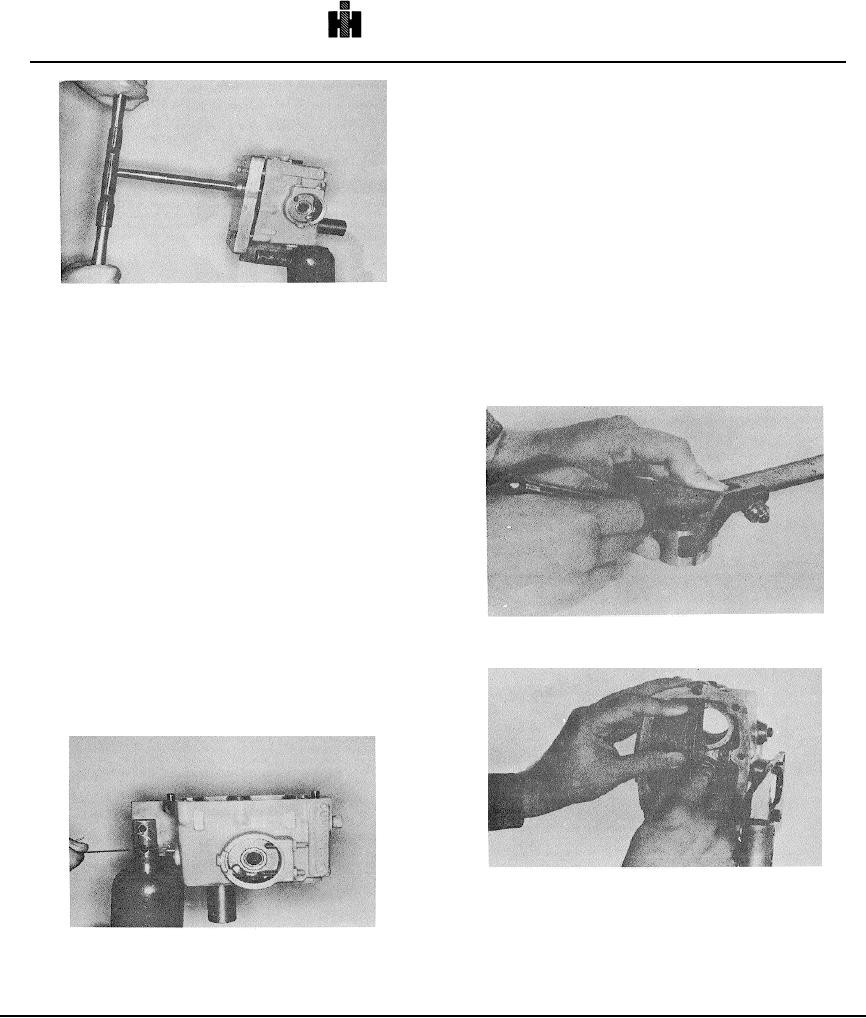

Note: Check through plug hole In bottom of PT (type G)

pump for spring dowel which secures barrel In fuel

pumps built after May 1963, before attempting to remove

governor barrel. Sometimes a wire hook, Inserted into

the hole provided, will pull the spring dowel. Fig. 5-18.

2. Check barrel bore in housing to determine whether

standard (1.5020 to 1 5025 inch [38.15 to 38 16 mm]

O.D.) barrel, 0.010 inch [0.25 mm] or 0.020 Inch [0.51

mm] oversize must be used. Minimum 0002 inch [0.05

mm] interference fit is required. Check bore for score

marks, remove If found.

Fig. 5-17, F514. Reaming drive shaft bushing with ST-

Assembly And Fitting

490

1. To locate a new governor barrel in the housing,

scribe a center line on barrel and housing, lining up the

fuel passages so fuel flow will not be restricted. Fig. 5.19

Governor Barrel, Plunger And Spring Pack Housing

and 5-20.

Inspection

1. Check governor barrel and plunger visually for wear.

2. If worn, replace governor plunger with a new plunger

of same class size as etched on face of governor barrel

Note: Due to hardness of governor barrel sleeve, it

wears very little. If worn excessively or if plunger shows

signs of scoring, barrel should be replaced.

Standard Governor Barrel Replacement

1. If governor barrel is worn or shows signs of scoring,

it will be necessary to heat housing in oven to 30 deg. F

Fig. 5-19, F516. Scribe center line on governor barrel

[149 deg. C) and press out governor barrel. Heat will

expand the aluminum housing and permit the steel barrel

to be pressed out with less chance of damaging housing

bore.

Fig. 5-20, F5136. Scribe center line on fuel pump

housing

2. Heat housing in oven to 300 deg. F [149 deg C].

Fig. 5-18, F5135. Removing locking pin from bottom of

barrel

3. Coat new governor barrel with high pressure

lubricant. Drop spring pack housing In place.

500