TRUCK SERVICE MANUAL

Aneroid

Aneroid Adjustments

Aneroids must not be removed, disconnected or otherwise

rendered ineffective on these engines, nor should settings be

altered to exceed those specified for the aneroid as shown In

Table 521.

Description

1. During acceleration or rapid engine load changes,

turbocharger speed (intake manifold pressure) change

inherently lags behind the power or fuel demand exercised by

opening of the throttle.

2. This lag does not exist in fuel system. therefore, an

over rich or high fuel to air ratio, usually accompanied by

heavy smoke, , occurs until the turbocharger "catches up "

3. The function of the aneroid is to create a lag In fuel

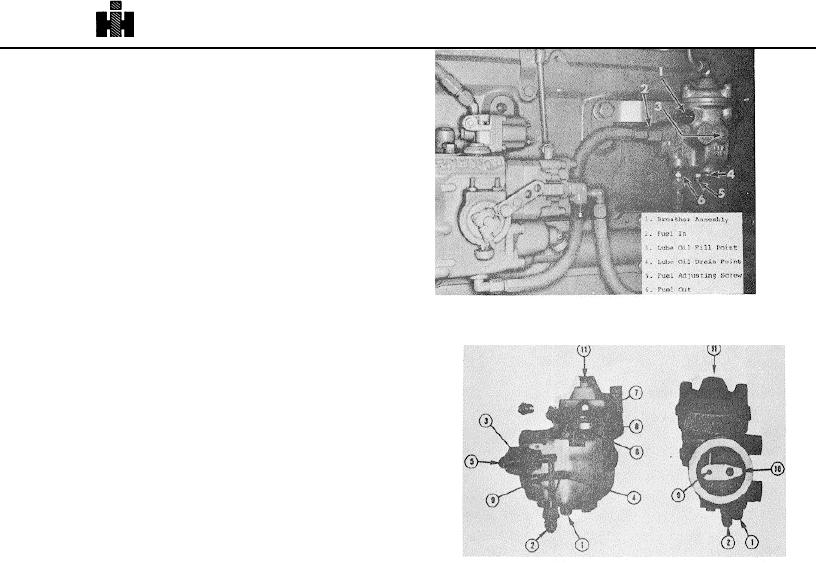

Fig 52 1, N 11026 Aneroid mounted on engine

system so response is equivalent to that of turbocharger, thus

controlling engine smoke level.

Fuel Flow

1. Fuel from outlet side of fuel pump enters aneroid and

goes through starting check valve area (5, Fig. 522). Aneroid

AR40600 series does not have a starting check valve but must

have a fuel check valve in supply line.

2. The starting check valve (3) prevents aneroid from

bypassing fuel at engine cranking speeds. For speeds above

cranking, fuel pressure forces the check valve open,

allowing fuel to flow to valve port (4) of shaft (9)

3. Shaft (9) and Its bore form the bypass valve This

Fig 522, F5244 Aneroid cutaway

shaft and bore allow passage or restriction of fuel flow in a

similar manner as throttle shaft and sleeve In PT fuel pump

9. The aneroid does not by-pass fuel under full throttle

lug down conditions until speed is low enough to reduce intake

4. allowed to pass through bypass valve is returned (2)

manifold air pressure to aneroid operating range (usually

to suction side (inlet fitting) of PT gear pump The

below engine stall-out speed.)

bypassed fuel reduces fuel pump output to engine and

reduces fuel manifold pressure In proportion to the bypass

Installing Aneroids On Fuel Pump Test Stands

rate. Fig. 521.

Precision setting

and/or checking of Aneroids is

5. The shaft and sleeve are bypassing fuel when arm

accomplished by simulating engine operation on a fuel pump

(10) of lever is resting against adjusting screw (1). The

test stand. Cummins ST848 Fuel Pump Test Stand must be

amount of fuel bypassed is adjusted by this screw, which

equipped as follows

protrudes from bottom of aneroid.

1. Fabricate a suitable bracket or mount the aneroid on

6. The lever arm connected to piston (8) by actuating

fuel pump test stand. This .bracket may be used to mount an

shaft (6)., rotates shaft, closing valve port. The lever is rotated

air regulator, such as used on ST790 or ST990 Injector Test

by action of air Intake manifold pressure (11) against piston

Stands, and a mercury manometer of suitable scale length or

and diaphragm (7), moving actuating shaft downward

30 inch pressure gauge of known accuracy.

against resisting spring force. Fig. 522.

2. Air pressure from regulator must be piped to top of

7. Anytime engine Intake manifold air pressure is above

aneroid to actuate bellows.

preset bellows "air actuation pressure," aneroid is "out of

system.

3. Tee off regulator air line (outlet) Into manometer or

8. The aneroid begins dumping when Intake manifold air

pressure gauge. Service Tool is ST1256.

pressure drops below preset value as happens after

deceleration In traffic, deceleration during gear shifts, down

grade motoring with closed throttle or down grade operation on

light load portion of governor droop curve.

540