TRUCK SERVICE MANUAL

pressure decrease is noted. Compare air pressure to that

shown in Table 5-2-1. This check must always be made with

decreasing pressure only. Internal friction in aneroid bellows,

spring and linkage causes air pressure requirements

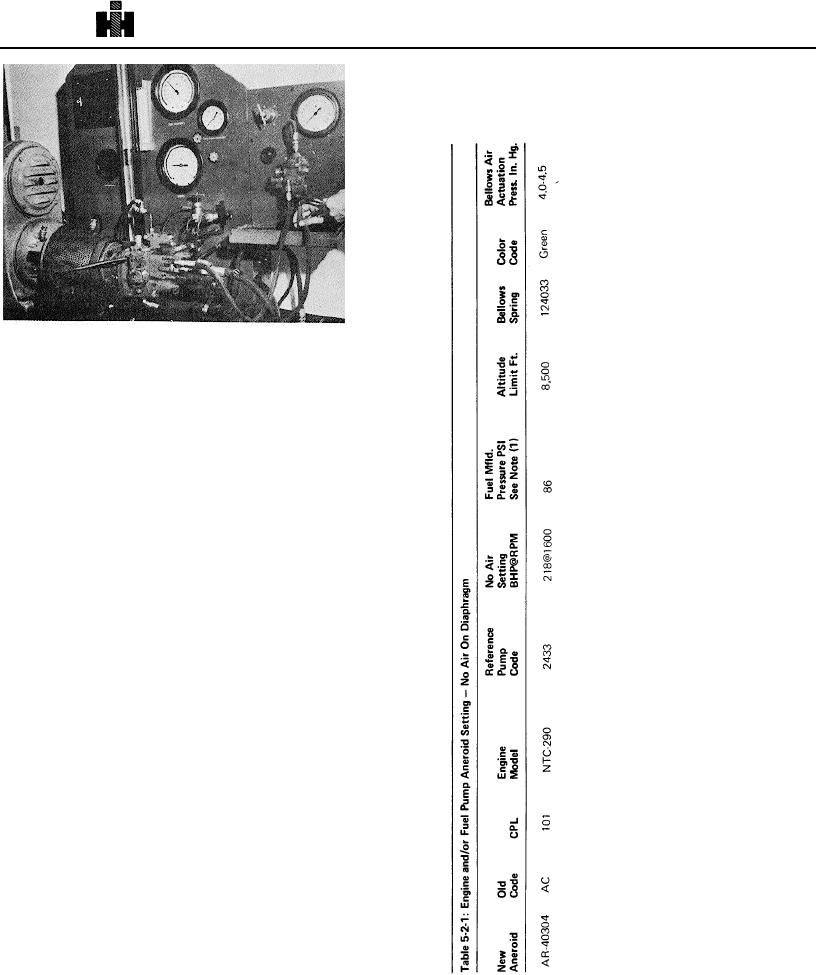

Fig. 5-2-3, F5287. Adjusting aneroid fuel screw

Testing Aneroid

Adjusting Fuel Screw

1. Mount a fuel pump on. fuel pump test stand which

has been calibrated to the same code as that on, or will be

used, on engine. For instance, if aneroid is intended for use

on an engine equipped with fuel pump calibrated to code

No.2049, use a pump set at same code (2049) to set aneroid.

2. Plumb aneroid to fuel pump in the normal manner.

Fig. 525

3. Start fuel pump test stand and purge all air from

system.

4. Adjust air regulator to appl y 30 inch [76.2 cm] Hg.

pressure on aneroid bellows.

5. Set fuel pump at rated speed calibration point

(Manifold PSI @ RPM and Flow Reading) specified for pump

code.

CAUTION

The flow control valve setting must not be altered during

the following checks.

Altering flow will give false

adjustments,

6. Reduce test stand speed to that shown in Table 5-2-1

under BHP @ Speed.

7. Set air regulator to "O" inches of mercury. Adjust

screw in bottom of aneroid housing to value specified under

"Fuel Manifold Pressure" for pump and aneroid code shown in

Table 5-2-1. Fig. 5-2-3.

Note: See section entitled, "Engine Altitude Derate and

Aneroid Settings" If engine requires a fuel pressure setting

lower than specified in Table 5-2-1 because of altitude.

8. Return air pressure to 30 inches [76.2 cm] Hg.

Decrease air pressure slowly while observing fuel pressure

gauge. When aneroid by-pass has just opened, a fuel

541