MOTOR TRUCK SERVICE MANUAL

INSTRUMENTS

list in the Parts Merchandising Catalog (MT-86),

with nuts and ferrules at both ends and a wire-wound

group 10.

flexible inner coil assembly with squared ends or crimped

on tip.

3. Select proper core size and cut to correct overall

length, using the swaging cutting fixture.

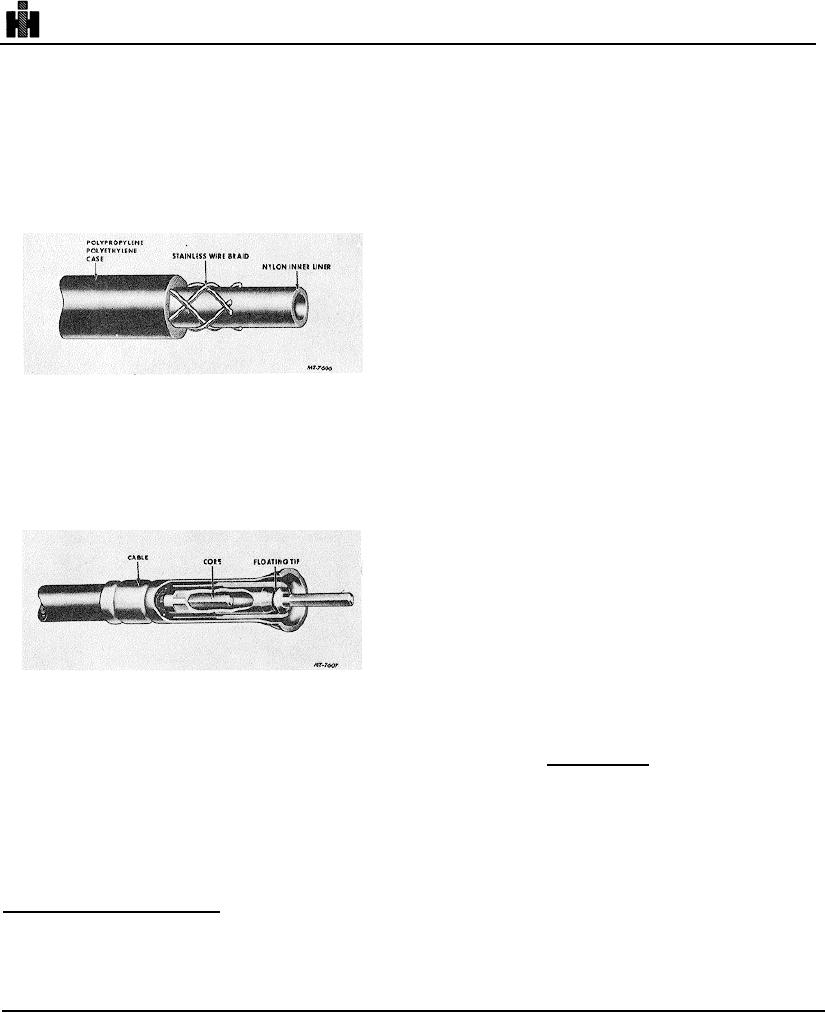

The semirigid type cable assembly consists of an

inner liner of nylon, then a wire braid followed by an outer

4. Select correct tips and position tips on core.

covering of polypropylene or polyethylene(plastic). It is

fabricated so that the three separate processes, Fig. 17,

5. Check overall length to be sure the core was cut to

become a single unit. The core is a wire-wound flexible

the correct length.

inner coil assembly.

NOTE: It is very important that the core is not too

long, since a long core wile produce a thrust on the

head of the speedometer when installed on the

vehicle.

6. Swage ends in place on core.

7. Lubricate core; refer to "LUBRICATION Flexible

Shafts".

Fig. 17. Semi-Rigid Speedometer Cable.

8. Install bushing at upper end of core if required.

In addition, some of the semirigid type cables use a

REPAIRING SPEEDOMETER AND TACHOMETER

"floating tip" at the lower end. This floating tip is

FLEXIBLE AND SEMI-RIGID SHAFTS

detachable from the cable assembly and when attached

allows the core to float, thereby minimizing the thrust on

Disconnect both ends of the shaft and remove from

the head of the speedometer, Fig. 18.

the vehicle. Pull the core out of the casing and check for

kinks by rolling on a flat surface. If a flat surface is not

available, take an end in each hand and roll core

between fingers. In either case, a core kink will show up

as a "hop" at the kinked point, Never reuse a kinked

core, because it will cause fluctuation of the

speedometer or tachometer pointer. Also, check for

frayed spots by running it loosely through your fingers.

Do not use a frayed core. A kinked or frayed core

usually indicates a casing with very sharp bend.

Fig. 18. Semi-Rigid Cable Floating Tip.

NOTE: Under no circumstances should a casing

have less than a six-inch radius bend.

Three popular sizes of speedometer cable cores are

available through regular service parts channels in bulk

LUBRICATION - Flexible Shafts

form. The three sizes of cores are . 130", .150" and

.187". In addition to the three sizes of cores, various tips

Flexible Cable: Every 15, 000 to 25, 000 miles apply

are also available which can be used in making different

a thin coat of graphite impregnated non-hardening

core assemblies.

grease on the core only. Lubricate only 3/4 of the way up

the core (starting at the lower end) and leaving the top

The following procedure has been prepared to assist

1/4 free of grease to eliminate any possibility of grease

in making a new core assembly.

getting into the instrument head. Hold the casing with

one hand and feed the core with lubricant into casing.

Fabricating Flexible Cable Cores

Semi-Rigid Cable: Apply a thin coat of "Lubriplate

1. Determine correct part number of core from the

110" or equivalent at reassembly or overhaul. Clean

Motor Truck Parts Catalog.

core. With about a teaspoon of lubricant in one hand,

feed the core

2. Locate this part number in the numerical

574