TRUCK SERVICE MANUAL

FUEL SYSTEM

b. A flexible connection (hump hose or molded elbow)

should be provided between the turbocharger and

support point of the piping to prevent the compressor

casing from being rigidly retained.

c. No more than 5 ft. 9 inches [1.8 ml of unsupported air

intake tubing should be attached to the turbocharger.

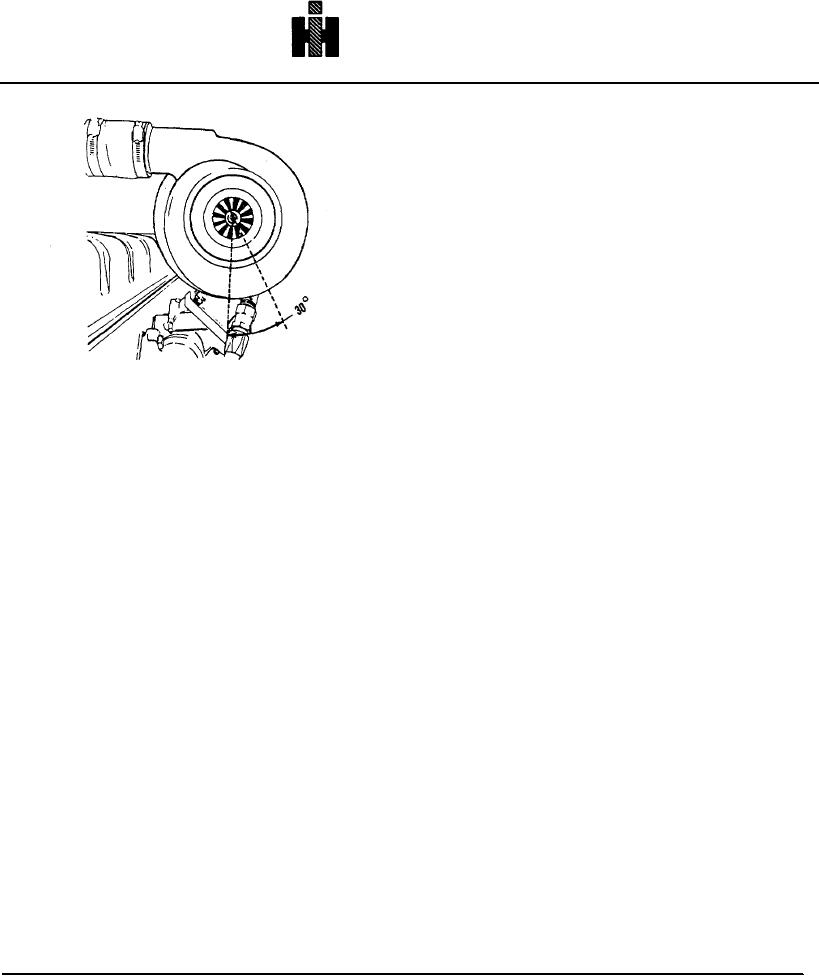

Fig. 10-40, T-333. Turbocharger mounting

7. Install hose connecting air outlet of turbocharger to

engine intake manifold connection.

8. Install air cleaner and exhaust piping.

9.

Check crankcase breather condition; excessive

crankcase pressure will cause turbocharger leakage.

Air And Exhaust Pipe Supports Both the air and

exhaust connections to a turbocharger require support

within a reasonable length to avoid excessive bending

moments on the turbocharger casing. They also require

a flexible joint between the turbocharger and the support

to compensate for movement, misalignment and thermal

expansion. The following are recommendations:

1. Exhaust Piping

a. The maximum bending moment of unsupported

piping at the outlet plane should not exceed 10 ft. lbs. [14

Nm .

b. A minimum of 12 inches [305 mm] of flexible

connection or two ball joints should be provided within

the first 4 ft. [1.2 m] of exhaust piping on turbocharged

engines to allow for thermal growth and to avoid

overstressing turbocharger components.

c. No more than 4 ft. [1.2 m] of unsupported exhaust

tubing or flexible connection should be attached to the

turbocharger.

2. Air Piping

a. The maximum bending moment of unsupported

piping at the compressor inlet plane should not exceed 5

ft. lbs. [7Nm].

569