TRUCK SERVICE MANUAL

FUEL SYSTEM

Assembly

Caution: All parts and work area must be free of

grease, oil and dirt to keep abrasives out of

turbocharger during assembly and to obtain correct

dimensional stack-up of parts and prevent premature

turbocharger failure.

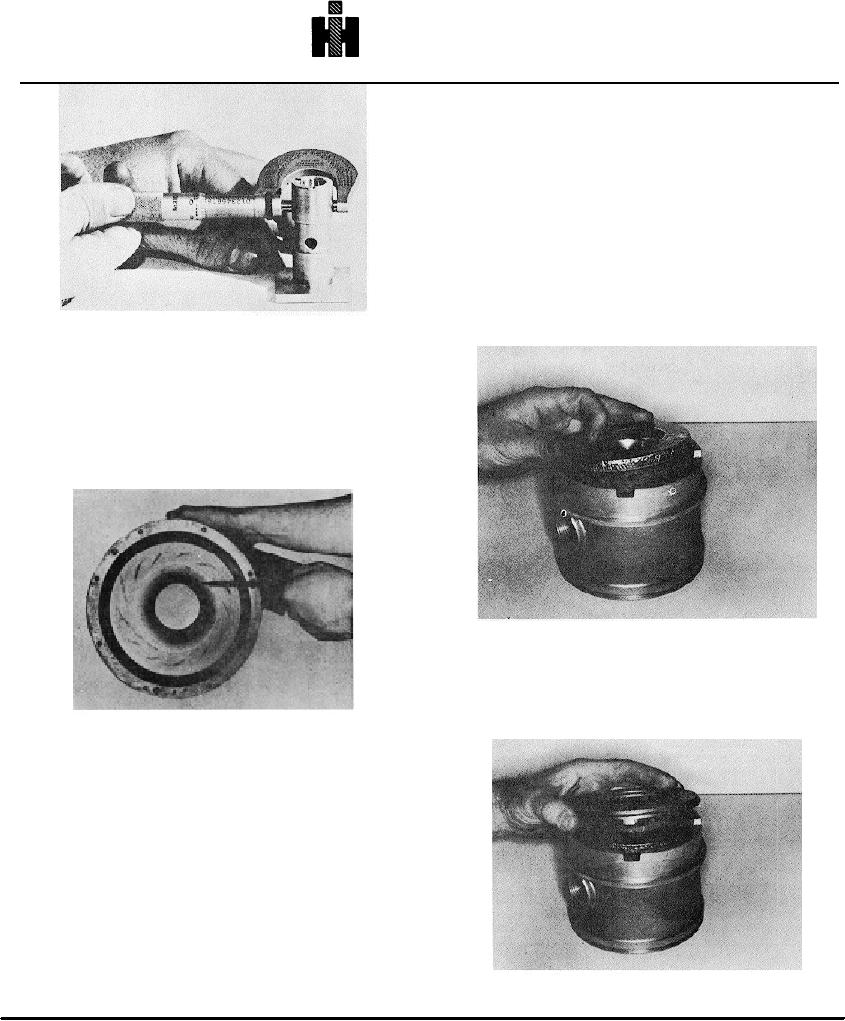

1. Use a piece of tubing or mandrel on shoulder of shaft

and check floating bearing end clearance on shaft. It

should be 0.005 to 0.009 inch [0.13 to 0.23 mm].

2. Position new metal covered insulation pad on turbine

end of bearing housing. Fig. 10-22.

Fig. 10-20, T-316. Measuring floating bearing O.D.

Collector Housing

Collector housing that is deeply scored from contact with

the compressor wheel, cannot be reused. Collector

housing contour is critical to proper turbocharger

performance. Fig.10-21.

Fig. 10-22, T-529. Installing insulation pad

3. Install heat shield on bearing housing. Fig. 10-23.

4. Position sealing rings In grooves on turbine end of

rotor shaft. Fig. 10-24.

Fig. 10-21, T-419 Inspecting compressor casing

If slight scratches or nicks are present, they may be

smoothed out with a very fine polishing cloth and the

collector housing may be reused. Discard If cracked or

distorted.

Miscellaneous

"V" clamps may be cleaned and reused unless they are

damaged.

Fig. 10-23, T-530. Installing heat shield

564