TRUCK SERVICE MANUAL

FUEL SYSTEM

Rebuild Instructions

Exterior of turbocharger should be cleaned before

disassembly. Mark compressor casing, diffuser plate, turbine

casing, bearing housing and clamps to facilitate assembly in

same position.

Disassembly

1. Remove fittings from lubricating oil inlet and outlet

ports.

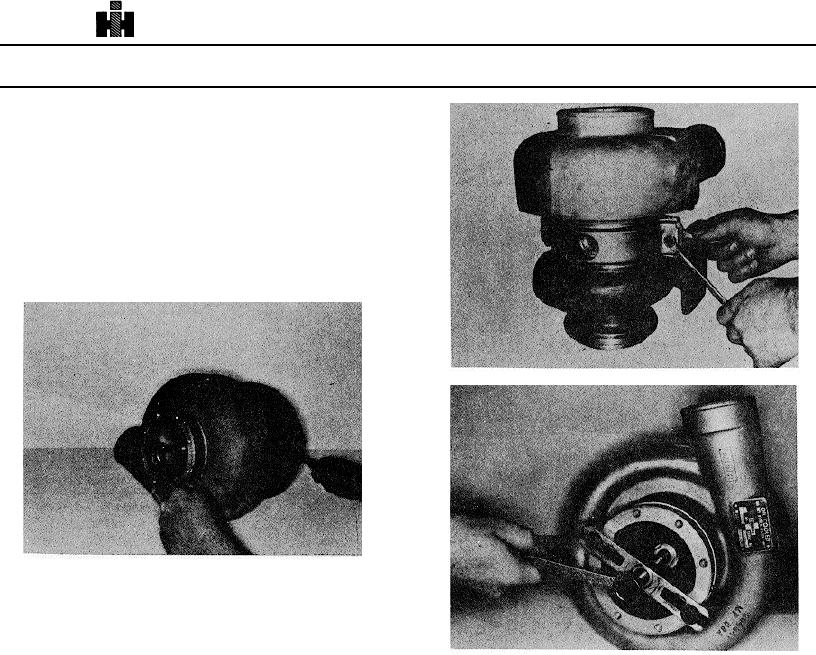

2. Remove self-locking nut from compressor end of

rotor shaft. Fig. 10-6.

Fig. 10-7, T-416. Removing "V" clamps

Fig. 10-6, T-428. Removing self-locking nut from compressor

end of rotor shaft

3. Remove self-locking nuts, flatwashers and bolts

securing V clamp to turbocharger. Fig. 10-7. Lift off V

clamps; discard self-locking nut, flatwashers and bolts.

Fig. 10-8, T-516. Pulling impeller from rotor shaft

4. Using ST-647 Puller, secure clamp to collector

housing with end of puller bolt on rotor shaft. Pull collector

housing, oil seal diffuser plate and compressor wheel from

8. Position ST-881 Bearing Support over bearing

bearing housing Fig. 10-8.

housing and against turbine casing. Fig. 10-11. Place

assembly on press. Fig. 10-12. Press rotor assembly and

5. Remove capscrews, lockwashers, securing collector

bearing housing from turbine casing.

housing to oil seal/diffuser plate.

9. Invert bearing housing and gently tap rotor shaft on

6. Tap gently to loosen and remove diffuser plate from

workbench, Fig. 10-13, to remove rotor assembly from

the collector housing. Fig. 10-9. Remove and discard sealing

bearing housing. Lift out rotor assembly.

ring. Lift out compressor wheel.

10. Remove heat shield and insulation pad from bearing

7. Remove teflon bearing insert and floating bearing

housing.

from rotor shaft. Fig. 10-10. Remove "O" ring from bearing

housing; discard "O" ring and Teflon bearing insert.

11. Remove

sealing

sleeve

assembly

from

oil

seal/diffuser

560