TRUCK SERVICE MANUAL

FUEL SYSTEM

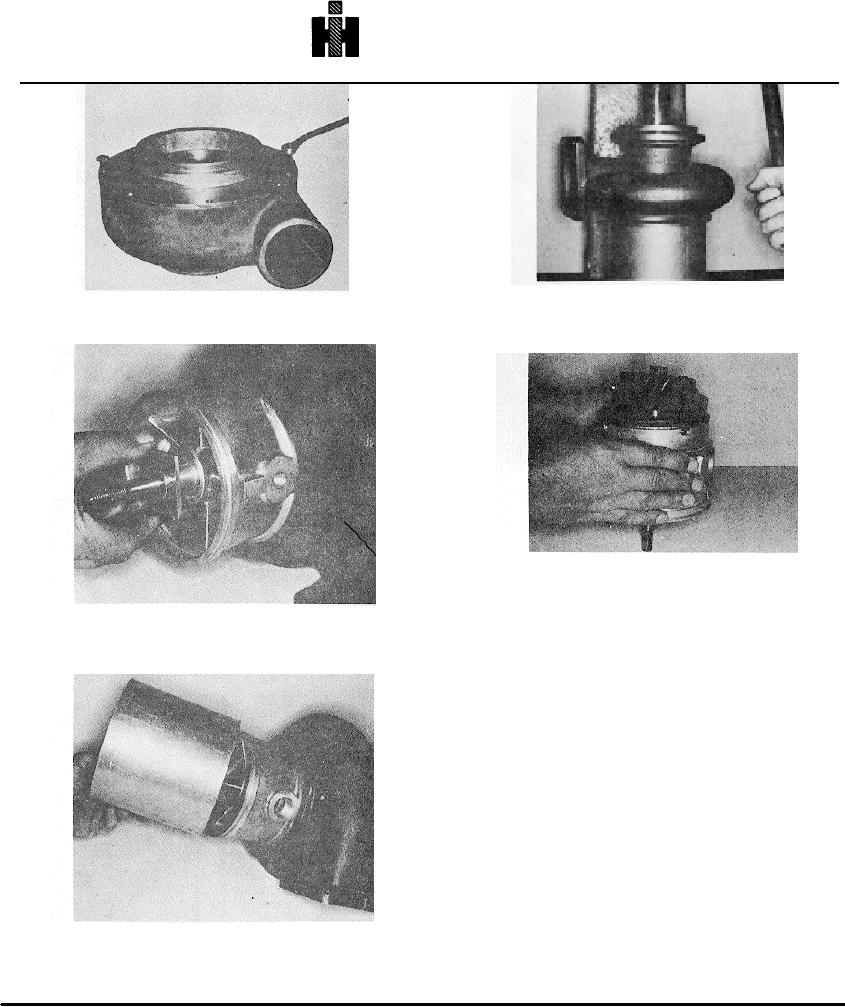

Fig. 10-12, T-519. Pressing rotor assembly and bearing

Fig. 10.9, T-418. Removing oil seal diffuser plate

housing from turbine casing

Fig. 10-13, T-430. Removing rotor shaft from bearing

housing

plate. Dsicard seal assembly.

Fig. 10-10, T429. Removing teflon bearing insert and

floating bearing form rotor shaft.

12. Remove sealing rings from grooves in rotor shaft.

Discard sealing rings.

Cleaning

Turbocharger parts accumulate hard, glazed carbon

deposits that are difficult to remove with ordinary

solvents. The cleaner used must be capable of removing

these stubborn deposits without attacking the metal.

1. Place all parts in a divided wire basket so parts will

not be damaged through contact. Do not pile in basket.

Be careful to avoid damage to all precision-ground

surface.

2. Immerse parts in Turko Super-Carb or similar solvent.

Caution: Never use a caustic solution or any type

solvent that may attack Aluminum, Stellite or Ni-

Resist alloys.

Fig. 10-11, T-518. positioning St-881 bearing support

over bearing housing and against turbine casing

561