TRUCK SERVICE MANUAL

FUEL SYSTEM

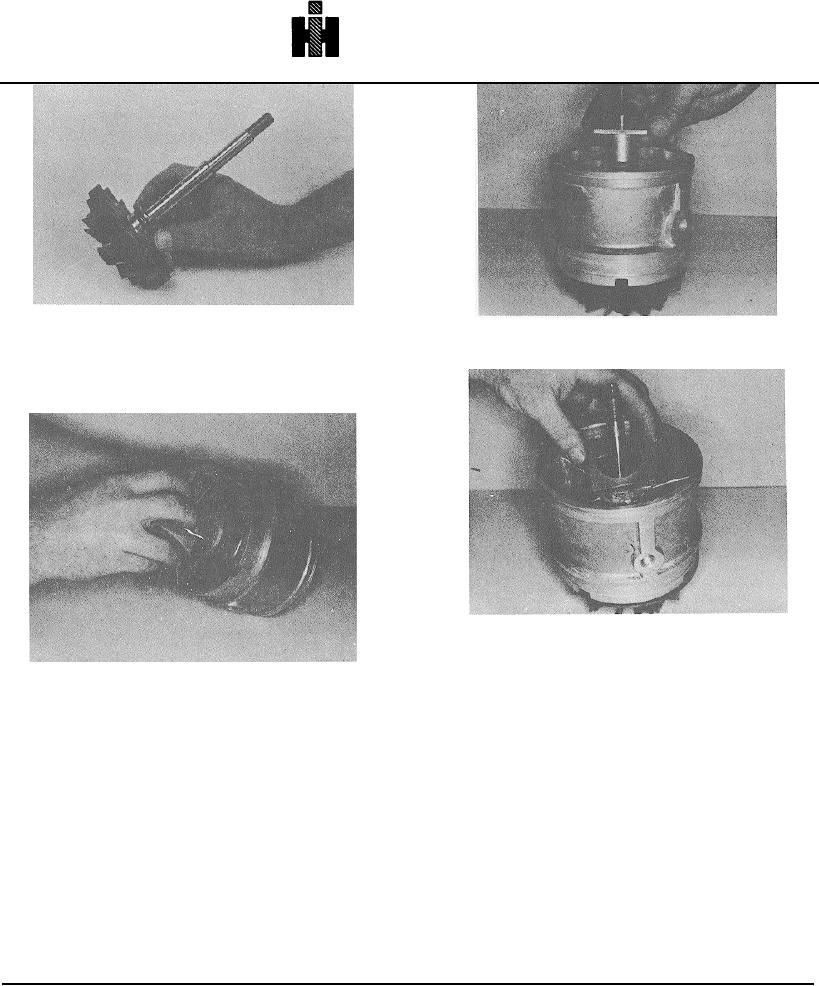

Fig. 10-24, T-433. Installing sealing ring

Fig. 10-26, T-434. Installing floating bearing

5. Coat bore of bearing housing with STP oil or

equivalent; Insert rotor shaft in housing. Fig. 10-25.

Fig. 10-27, T-435. Installing teflon bearing insert

oil seal sleeve and piston ring assembly. The second

Fig. 10-25, T-532. installing rotor assembly

assembly may be Identified by the thrust surface area of

floating bearing which is same outside diameter as oil

Note: Care must be taken to start sealing rings in

seal sleeve assembly and oil seal sleeve is 0.715 to

chamfer of bore to properly compress ring during

0.717 inch [18.16 to 18.21 mm] long.

installation.

6. Lubricate rotor shaft and floating bearing with STP oil

Complete assemblies are interchangeable but parts

or equivalent. Insert floating bearing over shaft and into

cannot be intermixed.

bearing housing bore. Fig. 10-26.

Caution: Coat thrust washer with clean lubricating

7. Position Teflon bearing insert over flange of floating

oil; handle only on edges of thrust washer. Thrust

bearing. Fig. 10-27.

washer must be retained in plastic enclosure until

Note:

Two floating bearing and oil seal sleeve

time of assembly.

assemblies are being used for service repair. One

8. Lubricate new red "0" ring lightly with clean engine

assembly consists of a floating bearing, thrust washer

lubricating oil and install in groove of bearing housing.

and oil seal sleeve and piston ring assembly; the second

Fig.10-28.

consists of a floating bearing and

9. Lubricate bore of oil seals and oil seal/diffuser plate

with STP oil or equivalent and insert oil sealing sleeve

assembly;

566