TRUCK SERVICE MANUAL

STEERING

ring on the side with the most clearance.

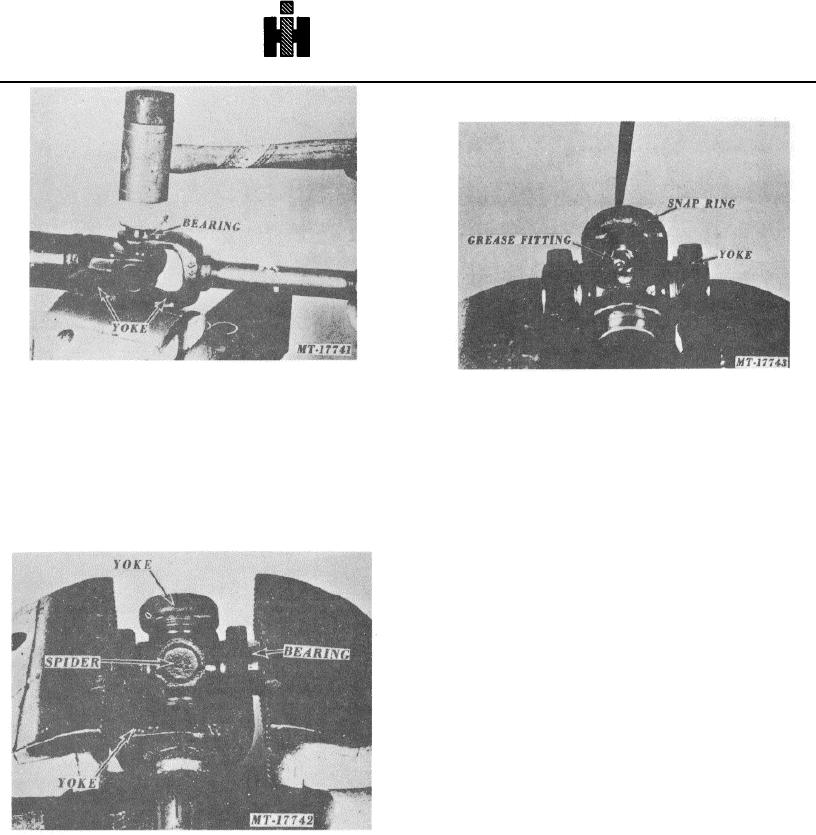

Refer to Fig.

13 and install snap ring.

Fig .

11 Start Bearing by Tapping with a Soft Hammer

Fig . 13 Snap Ring Installation

3. Insert spider through the opposite hole, without

7. After the first snap ring is in place turn assembly

bearing, swing it into place and down into the

over. The bearing with snap ring installed should

partially installed bearing.

be on the bottom. Rest yoke on vise and strike

4. Turn assembly over and tap the opposite

bearing which is on top, this will seat both

bearing part way into the yoke. Be certain to

bearings. Snap rings should rest against inside

start bearing straight in yoke.

milled surface of yoke. Install remaining snap

5. Place yoke in vise with bearings against jaws of

ring.

vise. Tighten vise slowly and the bearings will be

pressed into the yoke as shown in Fig. 12.

8. Lubricate universal joint with IH 251 HEP grease

or equivalent NLGI #2 multi-purpose lithium

grease.

STEERING WHEEL ALIGNMENT

Proper steering wheel-to-steering gear alignment

is designed into the steering assembly. Following are a

few alignment points to check at assembly or when

steering wheel alignment is a problem.

1. The steering wheel has open serrations at the

top that align with blind or closed serration on

steering shaft. The location of blind serration is

marked with either a center punch mark or chisel

mark on the end of the steering shaft as shown

in Fig. 14.

NOTE:

Do not attempt to adjust

steering wheel to straight ahead position

Fig .

12 Pressing Bearing Into Yoke

by relocating steering wheel to a

different serration.

6.

After pressing bearing into yoke the spider may

be off center in yoke. This is desirable because

2. Test drive vehicle on a straight and level (no

it permits installation of snap

crown) section of road for at least one-quarter

mile. Determine if or how far off center the

steering wheel is when the vehicle is going

straight.

660