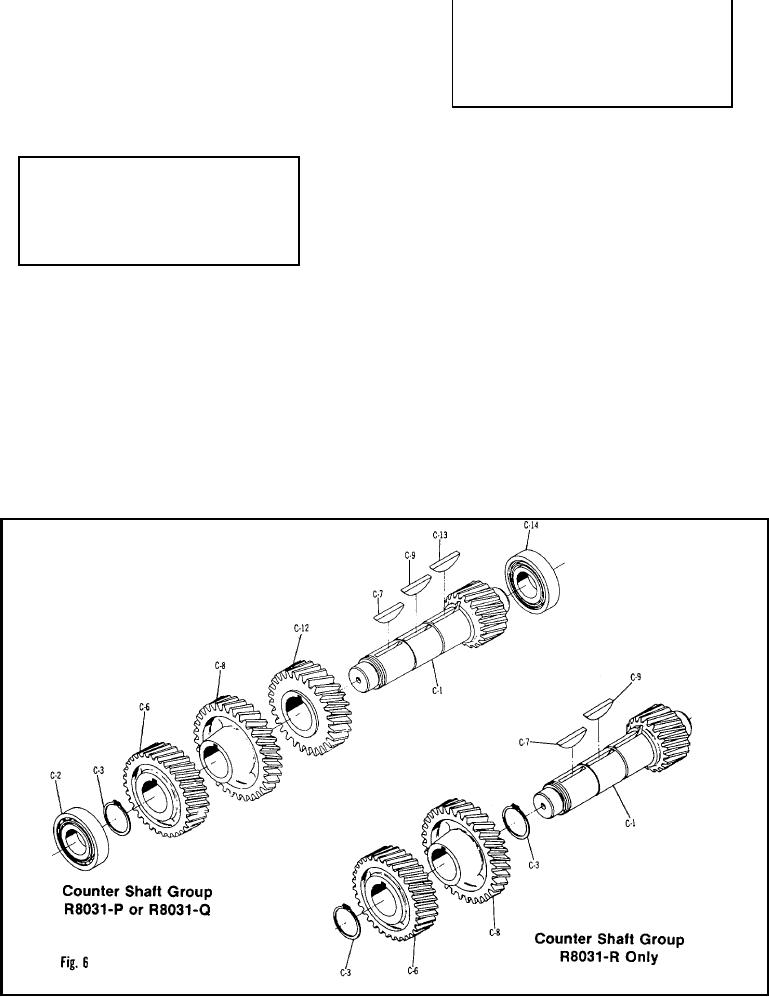

GEARS AND CASE

MAINSHAFT

ASSEMBLY

AND

INSTALLATION

NOTE

Drive gear pocket bearing (A-10) is

PARTIAL INSTALLATION OF MAIN DRIVE GEAR

made in two pieces. Be sure pocket

bearing is assembled with flanged end of

The diameter of the main drive gears used in the

inner race up or so it will be toward

R8000 Series auxiliaries are larger than the main drive

mainshaft.

gear bearing bore in the case. This necessitates a partial

assembly of the drive gear in the case prior to installation

of the mainshaft assembly.

3. Use soft hammer and tap outer race and roller

assembly of drive gear bearing (A-9) into front bearing

bore of case. Seat bearing tight against counterbore of

NOTE

case.

Assemble auxiliary drive gear bearing

4. Lower front end of drive gear (A-1) through top

(A-9) with outer race snap ring toward

opening of case and slide it forward into drive gear roller

gear teeth to prevent bearings from

bearing assembly (A-9).

operating with thrust load against snap

5. Check to make sure inner race of drive gear

ring.

pocket bearing (A-10) is in place in drive gear

counterbore.

1. Position inner race of drive gear roller bearing

(A-9) under arbor press with flanged end of inner race

MAINSHAFT ASSEMBLY:

up. Support inner bearing race and press drive gear (A-1)

Prior to assembly check the following parts for slip

into bearing. Be sure flanged end of inner race bottoms

fits, to insure free and easy assembly of the mainshaft

against front face of drive gear.

inside the case.

(a) Spline fit of direct and overdrive clutch

2. Position drive gear pocket bearing (A-10) in drive

gear (B-5) with clutch collar (B-6) and fit of

gear (A-1) and press into place.

internal splines on (B-5) with mainshaft

splines.

(b) Slip or loose fit of overdrive gear sleeve

(B-10) on mainshaft ground diameter.

832