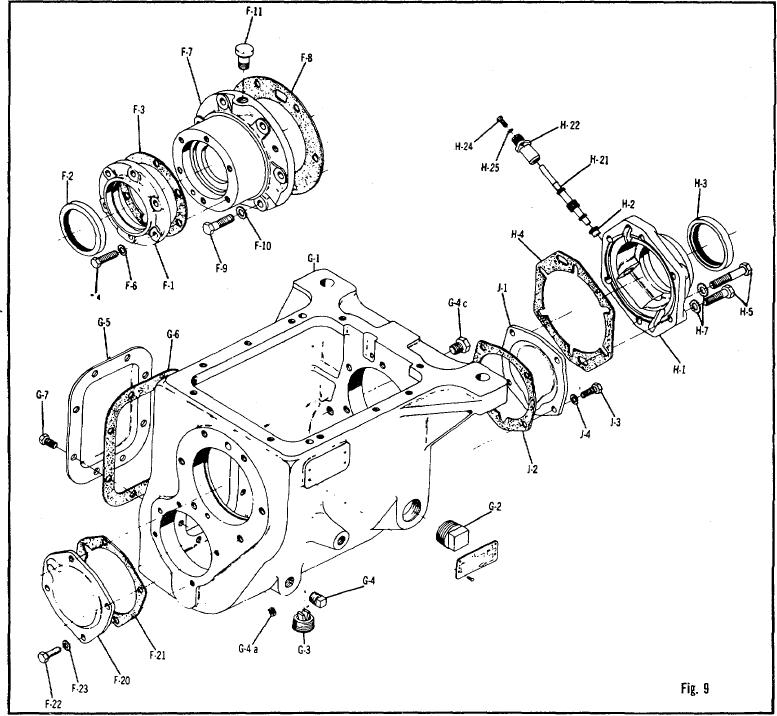

GEARS AND CASE

24. Locate and secure front bearing cap cover (F-l)

27. Shift clutch collars (B-6 and B-16) back into

to drive gear bearing cap (F-7) with cap screws (F-4) and

neutral and rotate drive gear to make sure all shafts turn

lock washers (F-6). Torque cap screws fo 40 50 lbs. ft.

free.

25. Place front transmission hanger over front

28. Use pressure type oil can to force lubricant down

bearing cap and assemble end yoke or flange with dirt

the oil holes and end slots of all floating gears on the

flinger on hub of yoke or flange (A-2). Assemble drive

mainshaft to flush out the grease and insure initial

gear with pusher tool. Observe the same caution and

lubrication of over-running gears and bearings. Use

procedure used in step 15.

regular auxiliary lubricant

26. Assemble flat washer (A-4) and nut (A-5) to end

drive gear nut to 500 550 lbs. ft.

836