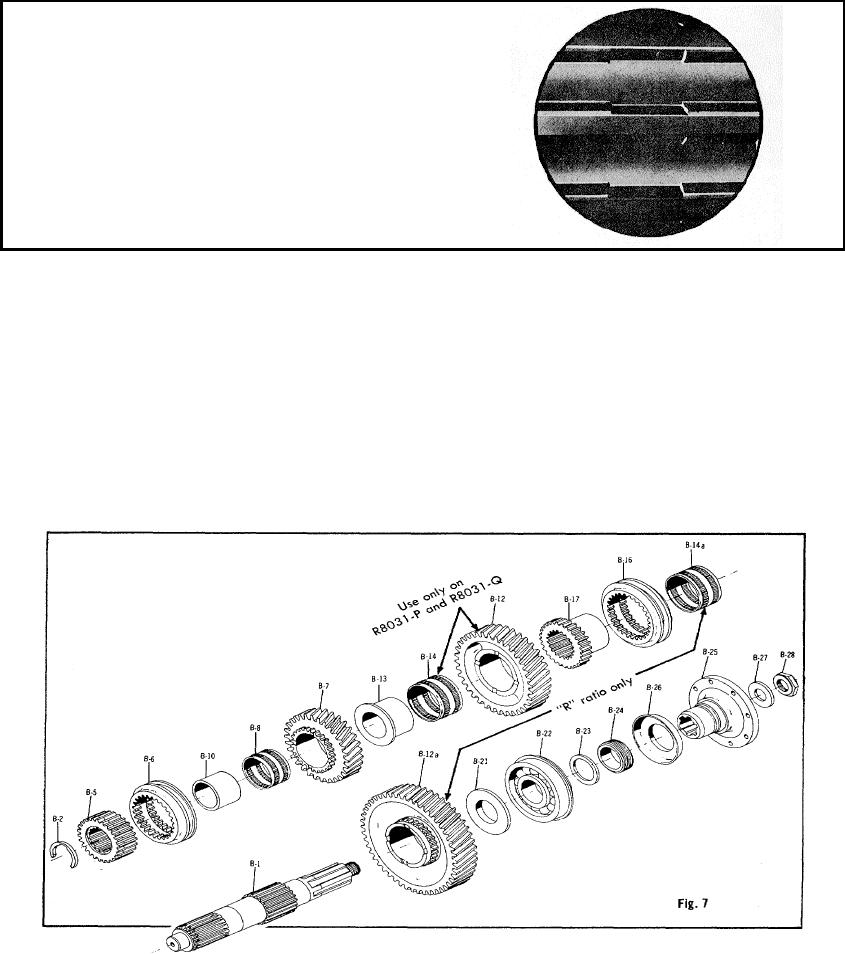

GEARS AND CASE

CAUTION

The splines of many Spicer clutching

gears, main shafts, etc., are equipped

with a machined relief called c "hopping

guard". With the clutch gear in the

engaged position, the mating gear is free

to slip into this notch, preventing the two

gears from "walking out of gear" under

load.

(See enlarged view.) This is not

a worn or chipped gear! Do not grind it

down or discard the gear.

A. Loose or caged needle roller bearings are used

left unfilled on all Dana/Spicer needle bearing

to carry the overdrive, underdrive and lo-lo gears (B-7, B-

applications. This will aid in preventing seizures by

12 & B-12a) on the mainshaft of the R8000 Series

allowing easier oil entry and free movement of the needle

auxiliaries.

bearings.

B. The individual gears, with sleeve and needle

D. To reassemble loose needle roller bearings (B-8

roller bearing sub-assemblies must be positioned in the

and B-14) the following steps are suggested. However, if

case and the mainshaft assembled through the rear

it is more convenient to assemble needle bearings to

bearing retainer bore.

inside of gears, rather than outside of sleeves, the

method is applicable.

C. Due to variations in tolerances and to provide

better bearing lubrication, Dana engineers recommend

If new parts are being installed, always check the

that loose needle bearings should not completely encircle

following to insure free and easy assembly and

the shaft. Space for approximately one needle should be

installation of mainshaft:

833