TM 5-3805-254-34

5-3.

STARTER MOTOR REPAIR (Con’t).

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never

exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to

avoid injury to personnel.

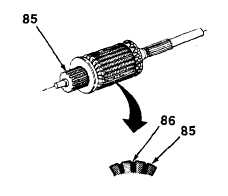

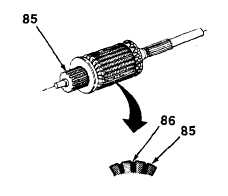

5.

Cut commutator (85) as required on lathe. When

cutting commutator, cut no more than 0.005 in.

(0.127 mm) at a time to remove scoring, pits, burrs,

or to return commutator to round. Then make final

cut of 0.002 in. (0.051 mm). Undercut mica (86) A2

in. (0.79 mm) deep and A2 in. (0.79 mm) wide.

Remove all loose copper and mica particles with

compressed air.

7.

Check length of brushes. If length is less than 0.50 in. (12.70 mm), replace brushes.

8.

Inspect brush springs for distortion. Replace brush springs if distorted.

9.

Inspect splines and gear teeth on starter drive for damage. Replace starter drive if splines or gear teeth are damaged.

10. Inspect bushings for damage and wear. If inside diameter of bushings is more than 0.005 in. (0.127 mm) larger than

shaft diameter, replace bushings.

11. Inspect all other parts for damage. Replace damaged parts.

c.

ASSEMBLY

1.

Install insulator bushing (83) on terminal stud (76).

2.

Install plate insulator (82) and field coil (84) on field frame (2).

TA703716

5-23