TRUCK SERVICE MANUAL

AXLE-FRONT

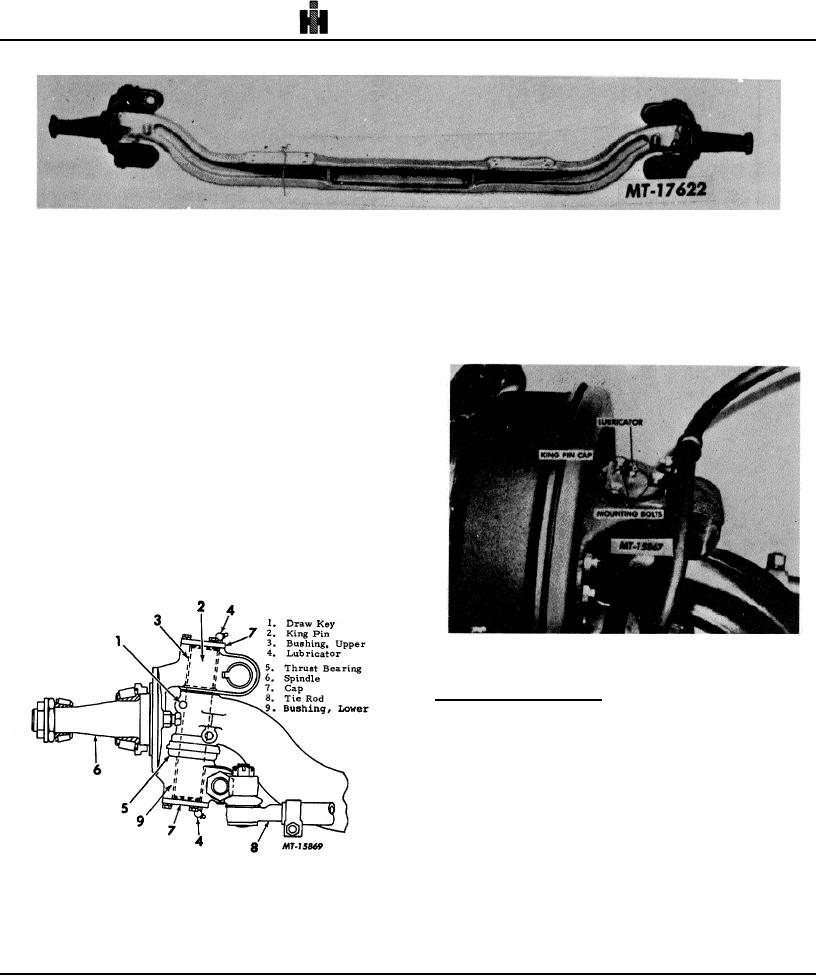

Fig.1

INTRODUCTION

turning freely about the pin. Bushings are of bronze or

teflon material, although some nylon bushings may be

The front axles mentioned herein are the heavy

encountered in service.

All bushings (EXCEPT

duty I-beam type, Fig. 1.

TEFLON) contain grooves which allow grease to flow

uniformly to high pressure areas. A lubricator is installed

Construction details for the most part are similar;

in both upper and lower knuckle pin bosses or knuckle

however, where major variations exist, these are

pin caps, Fig. 3.

individually explained.

AXLE CENTER SECTION

An "I-beam" type center section machined from

heat treated steel forging is used for these axles. Spring

pads are integral with the "I-beam".

STEERING KNUCKLE KING PIN

The axles are equipped with straight king pins

which employ one or two flats and are held in position by

tapered draw keys, Fig. 2.

Fig. 3

DISASSEMBLY

Wheel and Hub Removal

1. Raise front end of vehicle so that tires clear floor.

Block up securely at this position and remove

jacks.

(Do not attempt to disassemble or

perform knuckle repair with vehicle supported by

jacks only.)

2. Two types of wheel bearing adjusting nut lock

arrangements are used on the axles covered in

this section. Removal of these are as follows:

Fig. 2

STEERING KNUCKLE BUSHINGS

Steering knuckles are bushed--in-t-he upper and lower

pin bosses to assure

13