TRUCK SERVICE MANUAL

AXLE-FRONT

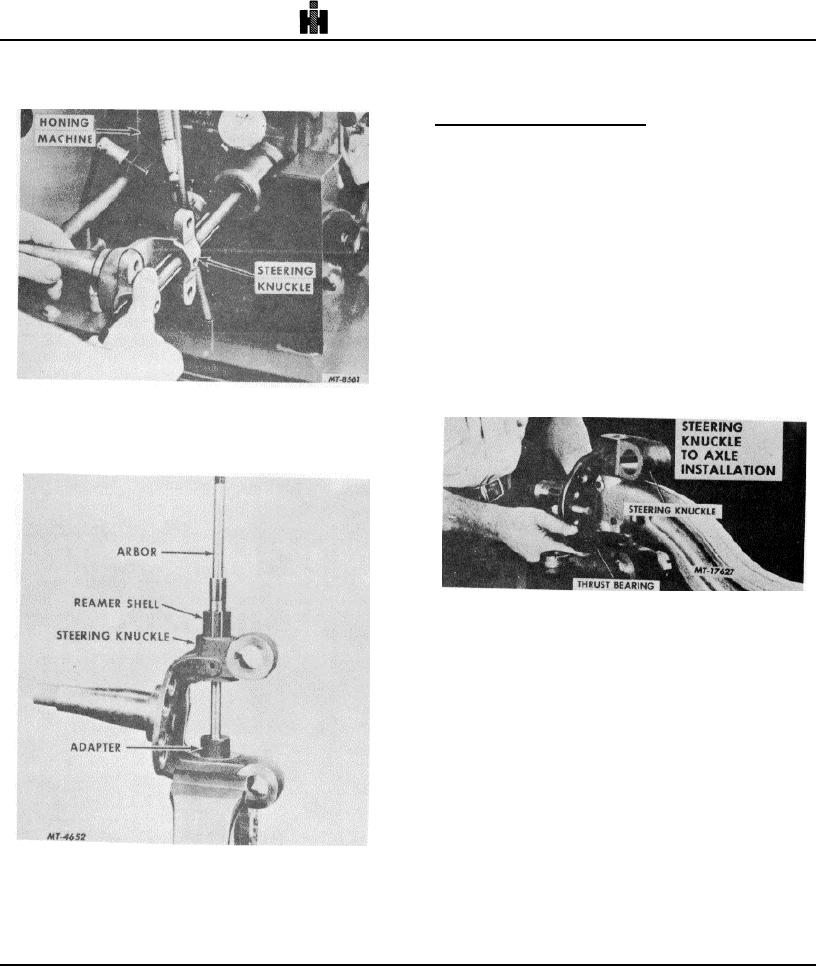

Line ream or hone new bushings to size shown in

NOTE: For best results, the use of steam

SPECIFICATIONS. An SE-2218 hone may be used to

cleaning equipment is preferred.

size bushings, Fig. 11.

KNUCKLE PIN INSTALLATION

IMPORTANT: Before installing the king pin

lubricate inside of bushing and outside of king pin with IH

251H E.P. grease or equivalent NLGI No.

2

multipurpose lithium grease to provide initial lubrication.

1. Make certain that knuckle pin hole in axle center

is clean and dry.

2. Position and support the steering knuckle

assembly on the axle center.

3. Slide the thrust bearing between the lower face

of axle center and lower steering knuckle yoke,

Fig. 13. Thrust bearings that are not marked

"top" to indicate proper installation position must

Fig. 11

be positioned with retainer lip down.

NOTE: If a reamer is used, it should be equipped

to pilot in one bushing, while reaming the

remaining one, or be long enough to ream both

bushings at the same time, Fig. 12.

Fig. 13

4. Align the steering knuckle yoke holes with axle

center and thrust bearing holes.

5. Place a jack under the lower side of steering

knuckle yoke and raise knuckle so that all

clearance is taken up between lower yoke, thrust

bearing and lower face of axle center end.

6. Check the clearance between the top face of

upper axle center end and lower face of upper

knuckle pin boss. The clearance must not

exceed .015". Washers and shims are available

in various thickness to take up this clearance

and hold it within the desired .015" tolerance,

Fig. 12

Fig. 14.

5. After the reaming or honing operation is

completed, the bushings and steering knuckles

must be thoroughly cleaned of all dirt and

shavings before king pin is installed.

17