AXLE-FRONT

TRUCK SERVICE MANUAL

(if removed) on chassis equipped with hydraulic brakes.

Clean and repack the front wheel bearing. Then

install the bearing in the hub assembly using new grease

seals, Assemble the hub and bearings on the spindle

being careful not to damage the oil seals or bearings.

Adjust wheel bearings referring to WHEEL BEARING

ADJUSTMENT. Then install wheel grease caps.

TIE ROD ENDS

The tie rods are of three-piece construction,

consisting of a tie rod and two rod end assemblies. The

ends are threaded to the rod and locked with clamp

bolts. Right and left hand threads are provided for toe-in

adjustment. Tension on ball stud in the rod ends are

self-adjusting and require no attention in service other

Fig. 14

than periodic inspection to see that the ball studs are

tight in the steering knuckle arms.

7. Align flat (or flats) to mate with draw key hole (or

holes). Drive knuckle pin through knuckle yoke,

Fittings are provided for periodic lubrication on

axle center and thrust bearing from top or

some types of tie rod ends. Where no fittings are used,

bottom side.

the tie rods have been lubricated at assemble and no

further lubrication is necessary.

8. Install the draw key (or keys). Drive the draw

key with flat side positioned to mate with flat on

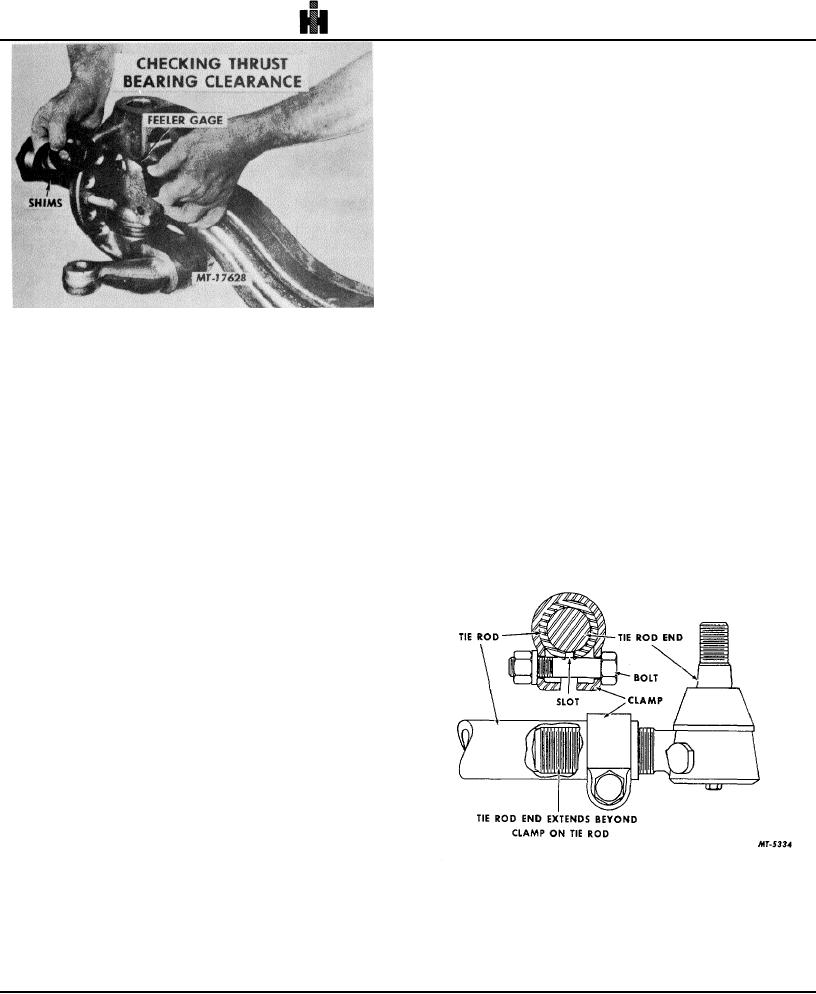

CAUTION: When tie rod, drag link or power

knuckle pin. Tighten nut to the specified torque.

steering linkage ends are replaced they must be

threaded into the tie rod sufficiently so that when the

EXPANSION PLUGS

clamp is applied, the clamping action will be directly over

1. On axles that have grooved holes, install lock

the threads on the ball joint end. Be sure that the end is

rings.

in far enough (past the clamp) to provide adequate

clamping and the bolt in the clamp is installed next to

2. On axles not grooved for lock rings, install

(over) the slot in the tie rod as shown in Fig. 15.

grease retainer plate and secure in place by

staking in four equally spaced places.

3. On units employing grooved knuckle pins that

protrude below the knuckle lower yoke, install

lock ring in groove.

COVERS, CAPS OR RETAINERS WITH FELTS

1. Install the cover or cap and gasket with cap

screws where used.

2. Install the felt, retainer and lock ring on

protruding straight pins that are not provided with covers

or caps.

Reinstall the tie rod tapered ends into the

steering arms and tighten the nuts to the correct torque

specification Then install the cotter pin. (Refer to TIE

ROD ENDS for replacement of tie rod ends.)

Reinstall brake chambers, connecting the push

rods also. Reinstall hydraulic brake cylinder fluid adapter

fitting

18