MOTOR TRUCK SERVICE MANUAL

BODIES AND CABS

WELDING PROCEDURES, INSTRUCTIONS

AND SAFETY PRECAUTIONS

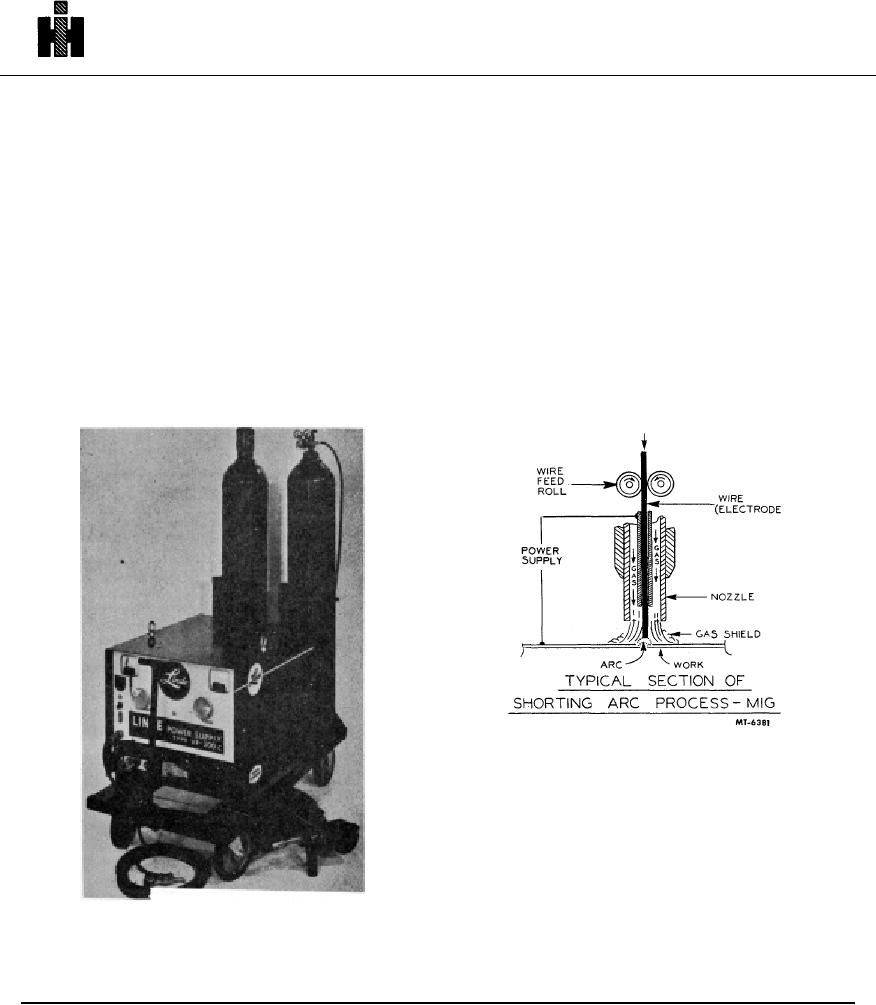

aluminum equipment using the SE-2165 Linde SWM-15

With the introduction of aluminum into the

Short Arc Welder, While similar welders are available

manufacturing of truck cabs, bodies and cab under

from other manufacturers, the SE-2165 (Fig. 1) welder is

structures, it becomes necessary for the operator of

illustrated herein. NOTE The gas containers shown in

welding equipment to understand a few special

Fig. 1 are not included with the SE-2165 but are obtained

precautions in order to assure satisfactory work when it

locally.

becomes necessary to perform any welding on

aluminum.

MIG welding is a process in which a consumable

bare electrode is fed into a weld at a controlled rate while

Generally, the operator of conventional steel welding

a continuous blanket of inert gas shields the weld zone

equipment will not find it difficult to handle the welding of

from contamination by the atmosphere. (Fig. 2) MIG

aluminum, providing he becomes familiar with the metal-

welding produces high-quality welds, at high welding

arc inert gas (MIG) method of welding. This manual

speeds, without the use of flux.

covers basic principles in making repairs on

Fig. 2. Diagram Showing Details of Shorting

Arc Process and the Inert Gas Shielding

The MIG process includes two distinctive techniques

or process variations, known as shorting arc and spray

arc welding. Shorting arc welding operates on generally

lower arc voltages and amperages than spray arc,

pinpoints the arc heat and produces a small fast freezing

weld puddle.

The spray arc process provides an

intensely hot, higher voltage arc and higher deposition

Fig. 1. Typical Arc Welder

rates.

(SE-2165 Linde VI-200C Unit Shown)

104