MOTOR TRUCK SERVICE MANUAL

BODIES AND CABS

area is depressed below the surface of the surrounding

area and the depression then filled with fiber glass or

plastic putty.

ALUMINUM ALLOYS

Sheet Alloys (Skin),

Aluminum, like many metals, is not generally used in

a "pure" form. In order to achieve certain desirable

properties, it is alloyed with other metals. In some

applications, specifications call for a class of aluminum

alloys containing magnesium as the principal alloying

ingredient. Those commonly used in sheet form are

5052, 5154, 5086, 5454; while alloys 5154, 5356 and

5554 are the commonly used welding electrodes.

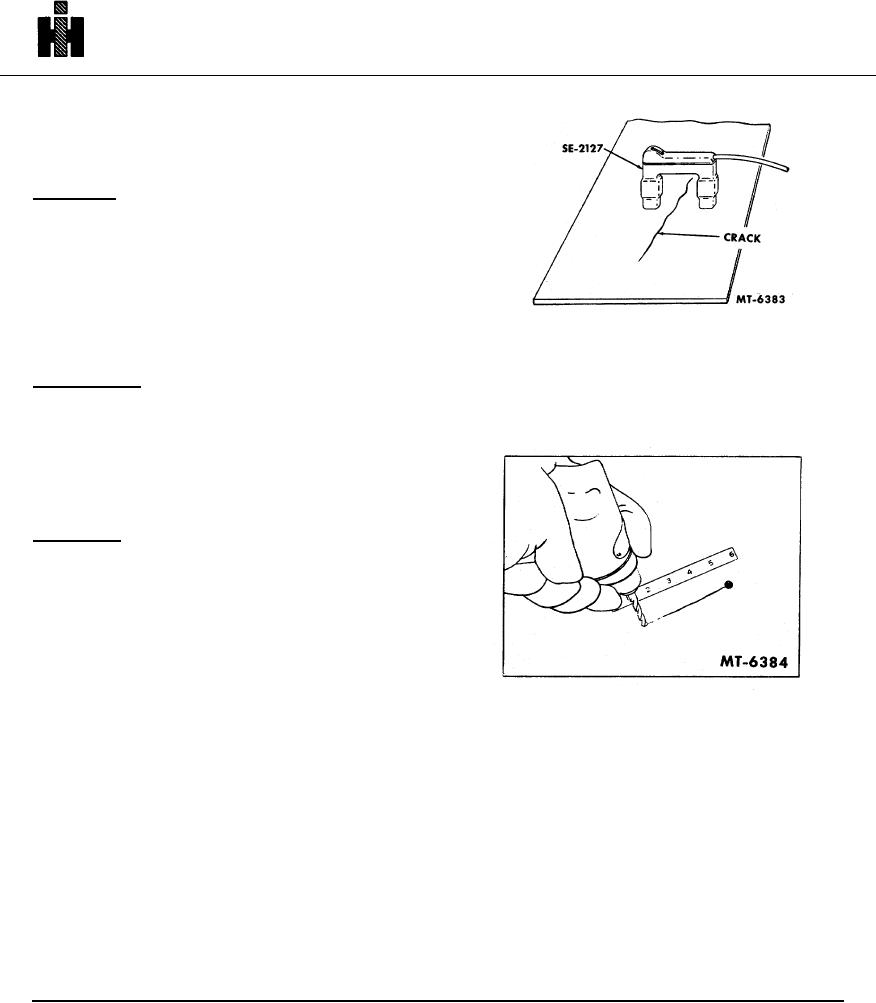

Fig. 4. Showing use of SE-2127 Portable White Line

Magnetic Inspection Tool. The crack area is

Structural Alloys

dusted with a special white powder which clearly

Rolled and extruded structural shapes used in

indicates the crack length when the magnetic

underframing and other applications may be alloy 6061,

field across the crack is generated.

6062 or 6063. These are heat treatable alloys having

both magnesium and silicon as alloying ingredients.

They are readily weldable to each other and to the

aluminum-magnesium series of alloys with 5154 and

5356 welding electrode and wire.

Crack Repair

Where cracks are to be repaired in the aluminum

sheet or skin, they must be prepared properly before

welding; however, it should be determined before making

the repair whether some additional reinforcement in the

crack area is required to prevent further problems.

Simple crack repair is as follows:

1. Locate the extent of the crack area or length. Often

the fine line of the entire crack length is not visible.

Use a dye penetrant to aid in locating the crack

length. Brush a small amount of the dye over the

suspected crack area. The dye will expose the

suffice. Do not run the chisel past the drilled holes at the

crack. If the SE-2127 Portable White Line Magnetic

crack ends (Fig. 3).

Inspection Tool is available, it can be used to expose

cracks in aluminum. This tool utilizes a magnetic

4. After the crack is widened, the work must be cleaned

field in conjunction with a white powder to indicate

on both sides if possible. Use a stainless steel brush

the crack.

Complete detailed instructions for

and make certain that all dirt, grease or paint has

operating the SE-2127 are included with the tool

been removed.

(Fig. 4).

2. After locating the crack and its extent, drill one 1/8"

5. Apply the weld to the prepared area by

hole at each end of the crack to prevent further

progress of the crack. (Fig. 5).

3. Using a thin chisel, open the crack a small amount

by driving down against the crack along its full

length. Do not widen the crack excessively. About

1/16" width will

107