TRUCK SERVICE MANUAL

BRAKES-AIR

CHAPTER IX

SPRING BRAKE AND TWO-WAY CONTROL VALVE

SPRING BRAKE CONTROL VALVE

automatic application will result when both primary and

(MIDLAND ROSS)

secondary systems have depleted air supply to the 28-35

psi.

DESCRIPTION

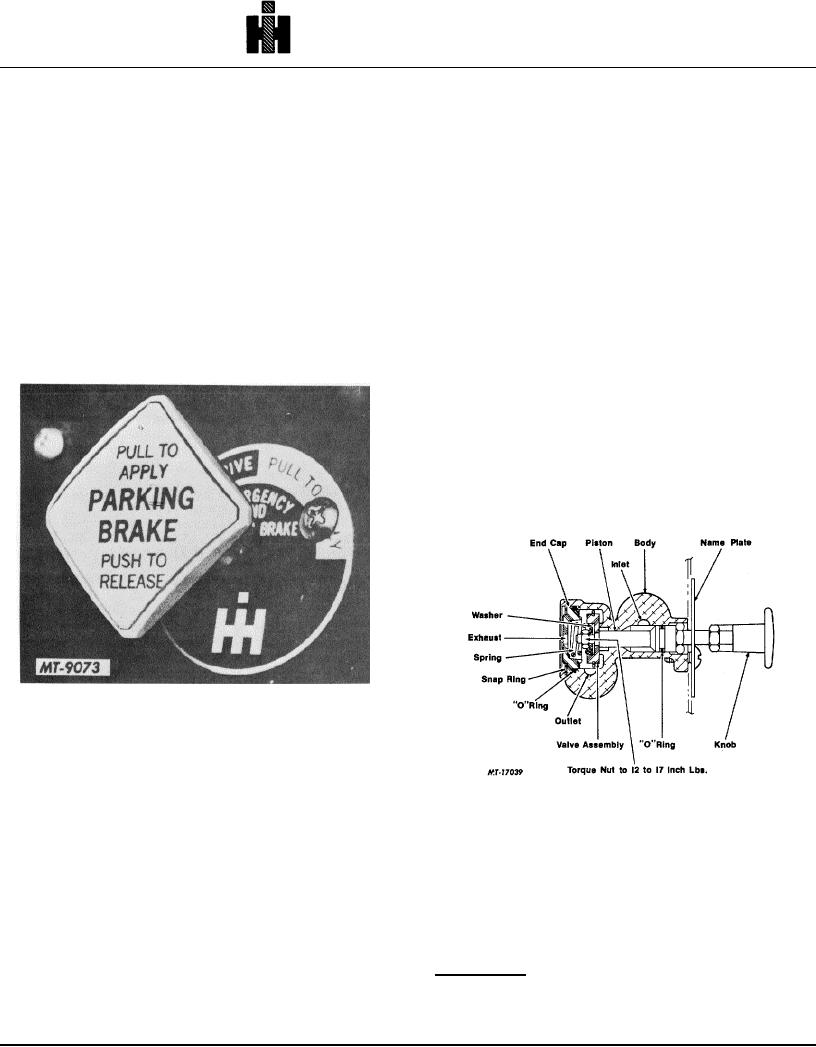

Refer to Fig. 2 for following operational description.

The spring brake control valve is a manually operated

Fig. 2 illustrates valve in applied (out) position.

valve of push-pull type. When the valve is pushed "in"

the valve is open to supply air. The "out" position closes

Pushing piston in moves valve assembly off body

off supply air and allows delivered air to exhaust to

seat until contacting end cap seat. Air pressure at inlet

atmosphere, applying the spring brakes. Valve also

has free passage to outlet and is blocked from

features a plunger pressure sensing arrangement which

exhausting to atmosphere.

provides automatic return to "out" position when brake

system air pressure approaches low energy levels.

Pulling piston out moves valve assembly away from

end cap seat and contacts body seat. Air pressure at

inlet is blocked from entering either outlet or exhaust

passages. Air pressure in outlet has free passage to

exhaust to atmosphere.

The spring in the valve assists to move piston out

automatically if inlet pressure drops and effective

opposing force across the valve seat is overcome.

Fig. 1. Spring Brake Control Valve

OPERATION

The spring brake control valve serves to app and release

the spring actuated parking brakes The valve is in the

"in" position under normal operation on either a straight

Fig. 2. Cross Section of Spring Brake Control Valve

truck or tractor-trailer. Air supply passes through the

valve delivering system pressure to retract and hold

MAINTENANCE

parking brakes in released position. Manual pull "out"

closes off air supply and vents delivered air to

Once each year or every 100, 000 miles the valve

atmosphere, applying the parking brakes.

should be removed, disassembled and a repair kit

installed.

When valve is pushed "in" it will remain in this position as

long as supply line is 45 psi o0 more. If air pressure

SERVICE CHECKS

should drop to 28-35 psi during normal operation the air

control valve will automatically apply, moving "out." The

Leakage Test

Use air pressure source equipped with in-line manual

shut-off valve, air gauge known to be accurate and

connection. Connect air source to

159