TRUCK SERVICE MANUAL

BRAKES-AIR

REASSEMBLY

the device being operated.

Lubricate O-rings, O-ring sealing surfaces and stem

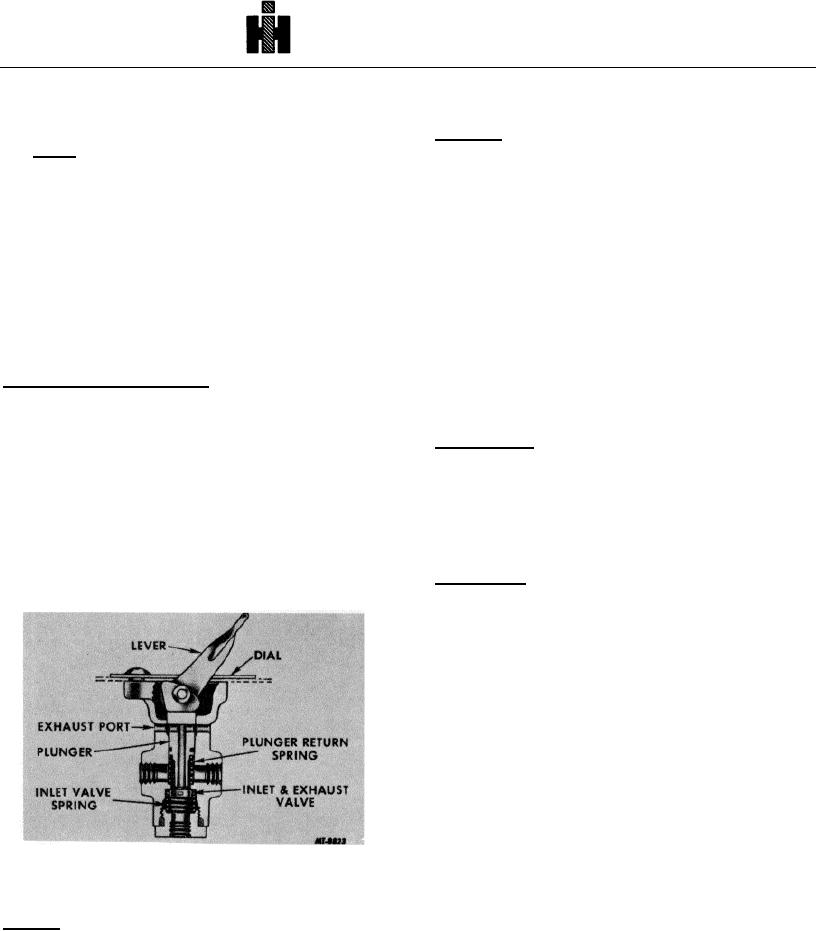

Releasing

When the lever is released, the plunger is raised by

with Item 3 of LUBRICANT SPECIFICATIONS (refer to

Fig. 4 for numbers in parenthesis).

the plunger spring and the inlet valve moves to its seat

and is held closed by the inlet valve spring and inlet air

pressure. Any air pressure in line or lines connecting the

1. Install new O-rings on stem (10) and piston (5).

two-way valve with the device being operated will be

2. Insert stem in valve body; then position piston (5)

exhausted through the hollow plunger and exhaust

in valve body over stem.

opening near the top of the valve.

3. Install stem nut (3).

MAINTENANCE

4. Install valve end cap (1) and new gasket (2).

Once each year or every 100, 000 miles the two-way

Before vehicle is returned to service, perform

valve should be disassembled and thoroughly cleaned.

SERVICE CHECKS on valve as outlined.

Replace all grommets and inlet valves worn or damaged

in any way.

TWO-WAY CONTROL VALVE

(BENDIX-WESTINGHOUSE TYPE TW-1)

SERVICE CHECKS

DESCRIPTION

Operation Test

Plug one delivery port and install an air pressure test

The TW-1 two-way control valve, which is an off-on

gauge in remaining port. Install second air pressure

valve, is mounted on the instrument panel and is

gauge in the air inlet line. With air connected to the inlet

primarily used in conjunction with various other air

port, place the lever in applied position. The air gauge in

devices in vehicle air systems. The systems in which

the delivery port should read the same as the gauge

these valves may be used are: transmission air control

installed in air inlet line.

valve, quick release valve, two-speed shift cylinders,

manually operated tractor protection valve and power

Leakage Test

divider lock-out system.

With air supplied to the inlet port of the two-way

valve and the lever in released position, use Leak

Detector Tester (SE-2326) at exhaust opening at top of

the valve (where lever enters valve) to locate any leak.

Move lever or button to applied position and check

exhaust opening with Leak Detector Tester (SE-2326) to

locate leakage past exhaust plunger.

REMOVE

1. Disconnect air lines at two-way valve.

2. Remove machine screws securing control valve

in place and remove valve.

INSTALL

1. Install valve using the machine screws. Position

Fig. 5 Lever-Operated Two-Way Control Valve

lever-operated or push button-operated two-way

valve on instrument panel with body of valve

OPERATION

behind instrument panel and dial or instrument

panel plate showing on front of panel.

Applying

When the lever is actuated in the delivery position,

2. Connect all air lines and perform tests outlined in

the hollow plunger of the valve is depressed and makes

SERVICE CHECKS.

contact with the inlet valve and unseats it. In this

position the exhaust passage through the hollow plunger

is closed and air from the inlet port has free passage

through the two-way valve and out the delivery port to

162