TRUCK SERVICE MANUAL

BRAKES-AIR

on the tubing and prevents collapsing the tubing when

the nut is tightened. The parts listing notes that there are

some sizes of tubing that are used only in accessory

piping systems in repairing accessory piping systems

tube supports are needed with all sizes of tubing except

1/8" O.D. if compression-type fittings are used.

Once the tubing has been connected and tightened

the sleeve has been crimped on the tubing and insert.

Since the sleeve has been compressed and distortion of

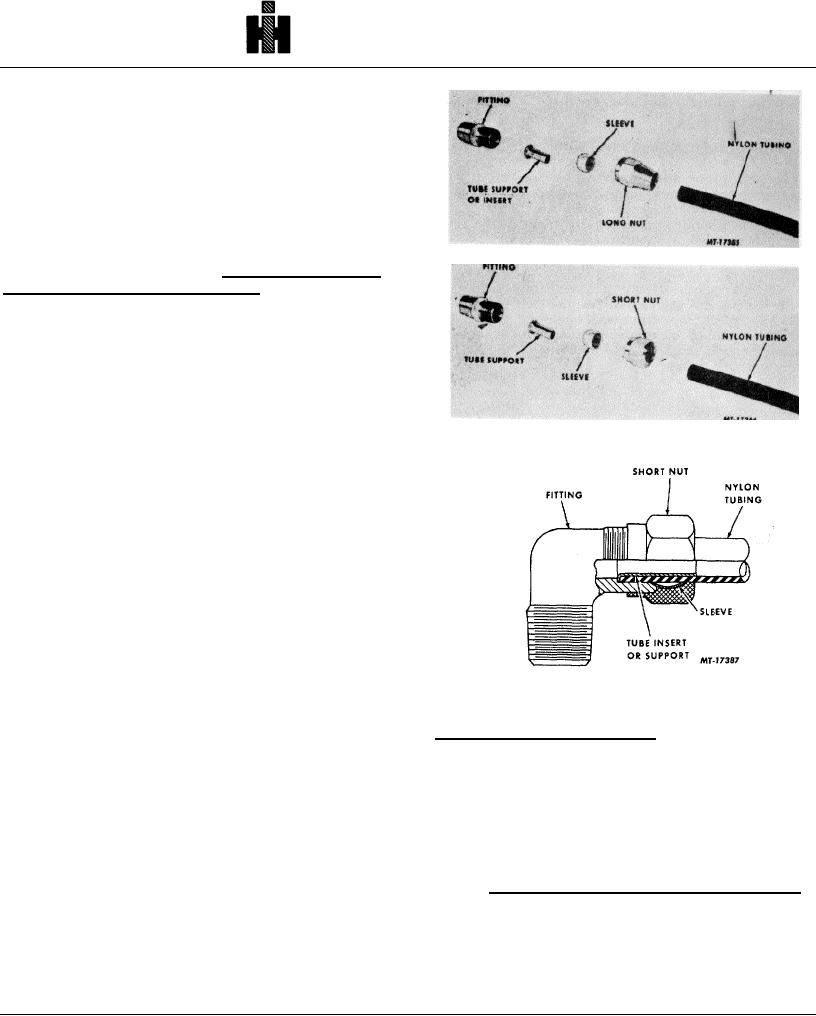

Fig. 6. Nylon Tubing assembly with Long nut

the insert may have resulted, the sleeve and inserts

should never be used the second time.

To assemble tubing ends for use with compression-

type fittings, the following steps should be followed

carefully.

1. Loosen and remove nut from fitting.

2. Pull tubing from fitting.

3. Repeat the same operations at other end of

Fig. 7. Nylon Tubing assembly with Short nut

tubing. If only one end of line needs repairing,

second end need not be disconnected if line is

long enough to permit repairing.

4. Cut the selected size of tubing to length. Be

sure to make smooth, square cuts. Either a

sharp knife or hack saw may be used.

5. Position nut on tube.

6. Position compression sleeve on tube.

*7. Insert tube support into tube.

*8. Position the tube, support and sleeve in the

fitting. Push tube in fitting until it bottoms.

9. Then install and tighten tube nut to secure

sleeve on tubing.

Fig. 8. Nylon Tubing Assembly Cross Section

10. Inspect tubing connections for air leakage. With

the tubing. and associated fittings charged to full

Nylon Tubing Special Instructions

system air pressure coat tubing lines and fittings

with soap suds to check for leakage. No

For the present this nylon tubing should not be

leakage is permissible. Leakage at a tubing

substituted in the field for any metallic tubing. In

fitting is sometimes corrected by tightening the

addition, the following precautions must be taken in the

tubing fitting nut. If this fails to correct the

use of nylon tubing.

leakage, replace the tubing fitting, tubing, or

both.

1. Do not use nylon tubing for any application which

would cause it to be exposed to temperatures

* No tube support is used with 1/8" O.D. tubing. Certain

below -40 degrees F or above +200 degrees F.

fittings used in accessory piping systems have the tube

support as an integral part of the fitting body. These

2. Do not subject nylon tubing to working pressure

fittings may be reused if no distortion of the tube support

in excess of 150 psi.

has occurred.

3. Do not use nylon tubing for frame-to-axle,

tractor-to-trailer or any similar line where a high

degree of flexibility is required.

167