TRUCK SERVICE MANUAL

BRAKES-AIR

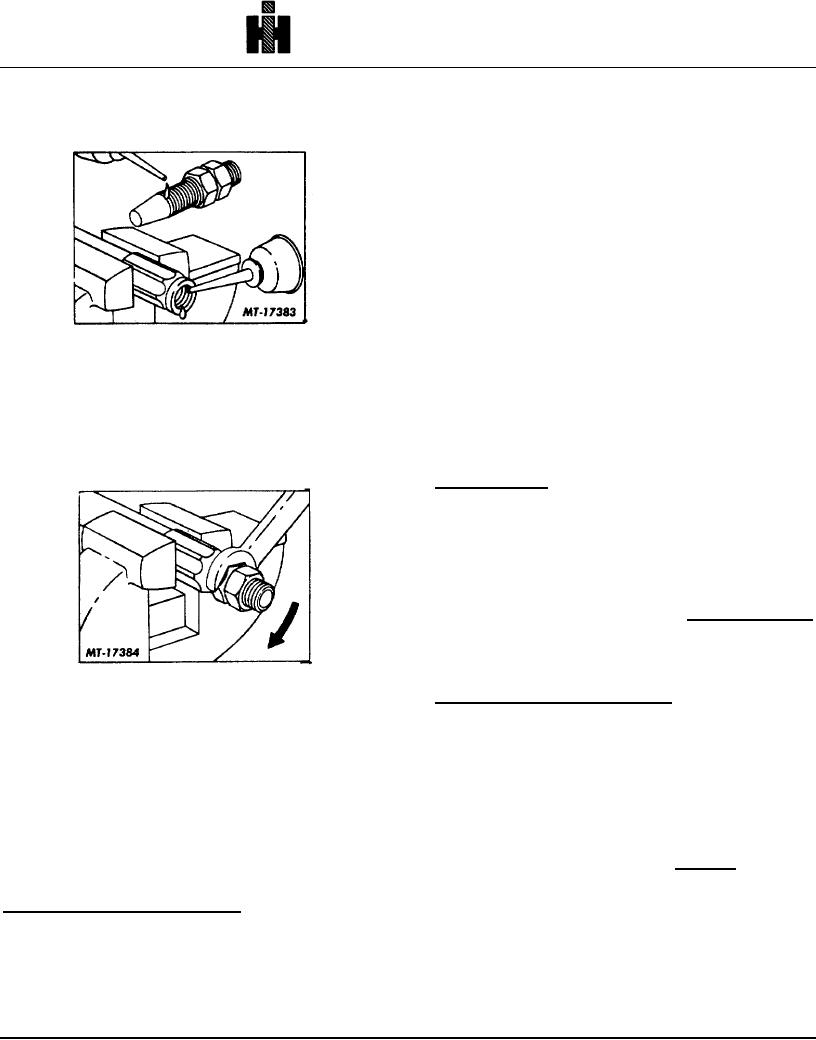

7. Reposition hose and socket in the vise as shown

1. High external temperatures will shorten the life of

in Fig. 4. Lubricate hose socket and fitting

a hose. Route hoses away from hot manifolds

threads.

and exhaust systems.

2. Abrasion of hoses will cause outer surfaces to

wear and weaken the hose. When installing

these flexible hoses avoid contact or

crisscrossing, sharp surfaces and contact of

moving parts (shift levers and pedals). Clip

hoses in place to prevent vibration, abrasion;

route hoses together and parallel. If the hose

cannot be clipped adequately, the hose must be

equipped with a protective conduit (cover). If the

hose being replaced has a protective conduit, be

sure to use a cover on new hose.

Fig. 4

3. Flexing of short hoses should not be allowed,

8. Position hose socket in swivel nut and

since this will tend to wear the hoses at the

fittings. If the hose must move, do not permit the

reassemble pipe adapter (if removed) to lock

hose to twist; keep the bend in the hose in the

swivel nut on the fitting. Thread the fitting and

same plane as the movement where the hose is

swivel nut (with pipe adapter) assembly into the

connected. Provide enough hose to permit any

hose as shown in Fig. 5 leaving 1/32" to 1/16"

movement which may be required. Avoid sharp

clearance between nut and socket so that the

bends or turns in the hoses.

nut can swivel freely.

NYLON TUBING

In past years nylon tubing of varying construction has

been used in such diverse applications as rear axle shift

control lines, windshield wiper motor supply lines,

transmission shift control lines and engine governor

control lines.

With production of nylon tubing as a replacement for

certain copper tubing in chassis air brake system

applications, a superior nylon tubing which is suitable for

all of the above applications as well as air brake system

applications is now being provided for field service use.

Fig. 5

Nylon Tubing Assembly Instructions

For the most part nylon tubing in air brake systems is

9. Repeat steps 5, 6, 7 and 8 on opposite end of

assembled much like copper tubing. The same fittings,

hose to install the remaining nut and fitting.

sleeves and nuts used with copper tubing can be used

with nylon tubing. Long or short tube nuts may be found

10. Lubricate the threads of the hose assembly

on chassis in service with nylon tubing (Figs. 6 and 7).

when connecting the lines (use light engine oil

Either nut may be satisfactorily used on the nylon lines.

sparingly).

NOTE:

If copper tubing is being

11. When installing the new hose assembly on the

substituted for nylon tubing, the short

vehicle be sure to check for possible leakage

tube nut shown in Fig. 7 must not be

and correct any leaks if leaks are present.

used. Either the short tube nut or the

long tube nut may be used satisfactorily

Hose Assembly Special Instructions

with nylon tubing.

Installation and routing of these hoses is just as

A tube support or insert will be used in all

important as special attention given to the installation of

applications of the nylon tubing in air brake systems.

the ends.

Common problems encountered with

The insert provides a stiff or rigid area for the sleeve to

installation and routing which will result in short service

be crimped or compressed

life of these hoses are:

166