TRUCK SERVICE MANUAL

ENGINE

3. Examine injector rocker lever sockets for a true

fit on injection links. Check sockets with a radius gauge

or by observation of a small protrusion at bottom of

socket. Remove and discard damaged or badly worn

injector rocker lever sockets by drilling a small hole in

lever above socket and knock out with a small punch and

hammer; after socket is removed, weld hole closed,

install and stake plug in hole.

4. Check rocker lever bushings for scratches,

pitting or scoring. Check rocker lever bushing inside

diameter with inside micrometers or small bore gauge. If

bushing exceeds 1.1286 inch [28.664 mm], press out

bushing with ST-691 Mandrel and Block. Clean lever

thoroughly and dry with compressed air. See Parts

Catalog for current replacement bushing part numbers.

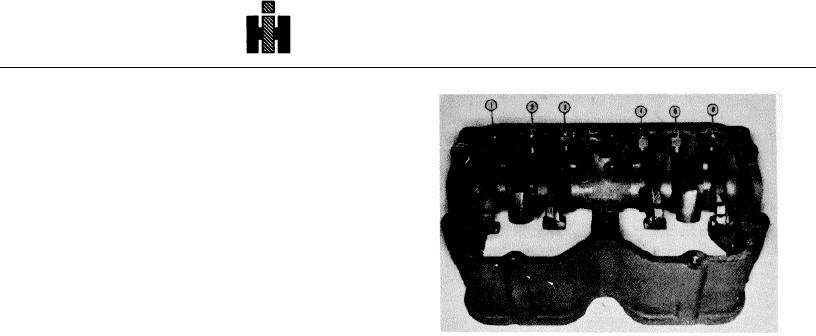

1. Exhaust Lever

4. Intake Lever

5. Install new bushing with ST-691 and arbor press.

2 Injector Lever

5. Injector Lever

3. Intake Lever

6. Exhaust Lever

a. On injector and exhaust valve levers, install

Fig. 3-4, (N10326). Rocker lever assembly

bushings so oil holes to crosshead nose or injector link

and adjusting screw are open for oil flow.

and secure shaft position with setscrew or oil spray

b. On intake valve levers, with oil drilling to

nozzle. Check all levers for freedom of movement on

crosshead nose end, install bushing so "nose" hole is

shaft to prevent galling.

closed and so "slot hole" is in line with adjusting screw oil

hole. Do not bore steel bushings.

Note: Oil spray nozzles are used on 80 deg. tilt engines.

6. Check intake and exhaust rocker lever-to-

Use ST-1182 Alignment Tool to obtain proper alignment

crosshead contact surfaces. If worn or damaged, grind

of oil spray holes in nozzle to permit oil flow from rocker

to original contour or replace with new rocker lever.

lever shaft to valve mechanism. Secure spray nozzle in

desired position with jam nut.

7. Check rocker lever shaft for wear or scoring. If

shaft has shoulders or ridges due to rocker lever action

5. Coat expansion (cup) plug contact surface with

on shaft, replace with new rocker lever shaft. See Table

sealant. Install new expansion plug in rocker lever

3-1 (2) for shaft dimensions. Flush out shaft bore and

housing using ST-1053 Driver.

dry thoroughly.

8. Current shafts are 12.880 inch [327.15 mm]

CRANKCASE BREATHER

long, older shafts are 13, 060 inch [331.72 mm]. Older

shafts can be reduced to new shaft length if oil leakage

Four different types of crankcase breathers are used on

has been encountered at the shaft cup seal plug.

855C.I.D. Series Engines. Mesh element with vapor

Machine equal amount from each end of shaft.

barrier, mesh element, paper element and screen

ASSEMBLY

element.

1. Install adjusting screws and locknuts in rocker

levers.

1. Remove cover, screens and baffle or element

from breather body; discard paper element.

2. Install cup type plug in rocker lever shaft with

ST-863 Cup Plug Driver. Coat rocker lever shaft with

2. Clean vent tube, screens and baffle or mesh

clean lubricating oil.

element in an approved cleaning solvent. Wipe out

3. Start shaft into housing, install levers on shaft as

breather housing.

shaft is pushed through housing. See Fig. 3-4 for

correct position of levers.

3. Assemble baffle, screens or element and new

gasket in body. Replace cover.

Note: Current engines using aluminum rocker lever

4. Index locking hole in shaft with locking hole in

cover with baffle plate, Part No. 210051, installed, do not

housing

have baffle or screens in crankcase breather body.

364