TRUCK SERVICE MANUAL

ENGINE

Table 1415: Normal Lubricating Oil Pressure

Idle (525620rpm}

Rated Speed

PSI [kg/sq. cm]PSI [kg/sq. cm]

10 [70] Minimum

40/75 [2.80/5.25]

Note:

Individual engines may vary from above

pressures.

Fuel Pressures

For fuel pressure reading and adjustment, refer to Fuel

Pump Calibration

Overspeed Stop

Overspeed stops, when used, are set to trip and shut off

fuel supply when engine exceeds maximum rated speed

by approximately 15%. After determining and correcting

cause of overspeed stop trip, reset in running position.

Engine Fuel Rate

ST1190 Fuel Consumption Measuring Device operates

by drawing fuel from fuel tank, then through flow meter.

Return fuel from injector drain is routed through float

tank so when float tank is filled, float valve opens and

allows return fuel flow to flow meter. Makeup fuel or

amount of fuel being consumed by engine will flow

through flow meter thus showing rate of fuel

consumption in pounds per hour. See fuel pump

calibration manuals.

Blow-By Readings

1. Manometer readings must be taken frequently during

runin test so mechanic will note any blowby increase at a

given speed and load. If there is any indication of blowby

increase, engine speed must be reduced for a few

minutes and then brought back to the original setting.

2. During each power check, keep a constant check on

the manometer; if pressure rises, more runin is required.

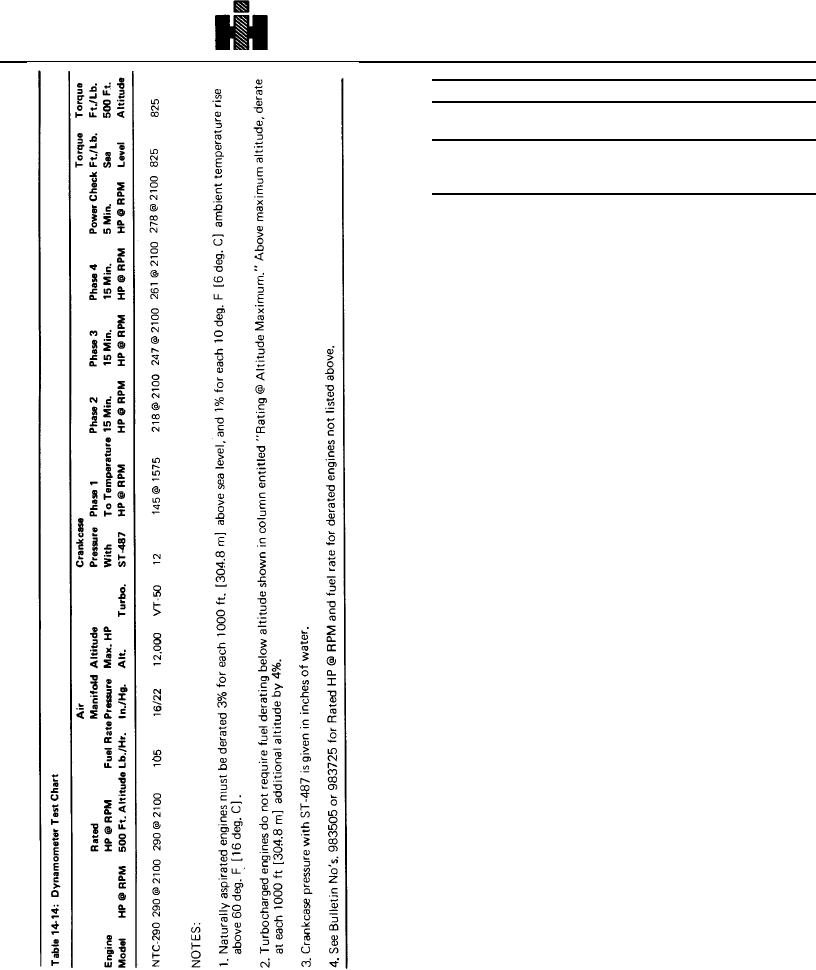

Representative pressure limits for engine running at

governed speed and pulling 96 to 100% of rated

horsepower are given in Table 1414. If pressure is

greater than values listed at end of testing period, engine

should be checked as follows:

a. Naturally aspirated engines:

Operate 30 minutes extra at 96 to 100% rated load and

rpm. If there is no rapid change in excess of 1 inch [25.4

mm] of water and maximum reading does not exceed

100% of representative pressure, blowby is acceptable.

414