TRUCK SERVICE MANUAL

FUEL SYSTEM

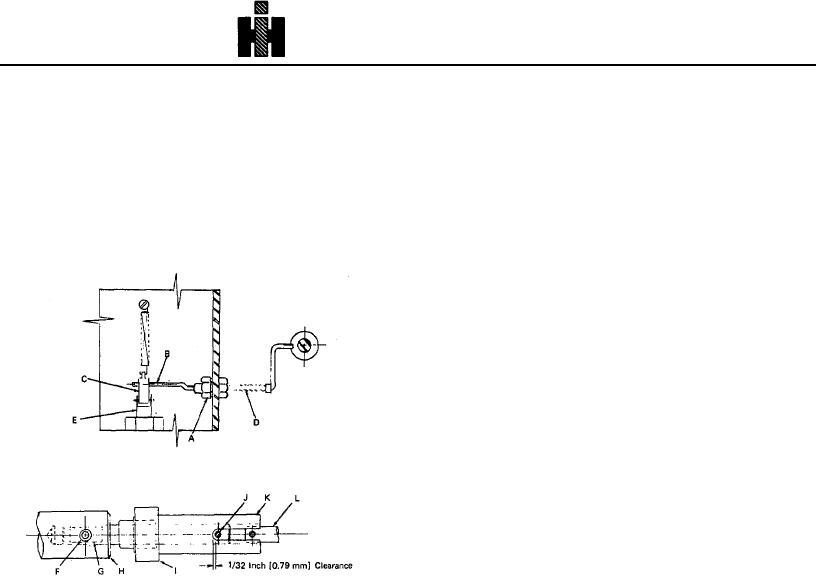

c. Gauge line contacting frame or other member of

Clutch Adjustment

test stand thereby transmitting mechanical

1. Manually engage clutch by fully depressing

vibration into gauge.

solenoid plunger (shown above In "Clutch Arm

Removal Procedure"). With clutch held in this

position, the cross pin (J, Fig. 6-1-77A) should

clear the driver U-slot by approximately 1/32 inch

as shown in the drawing.

2. Tighten set screw (F, Fig. 6-1-77A) against flat

provided on clutch shaft (G, Fig. 6-1-77A).

A.

Nut

E.

Plunger

I. Collar

B.

Clutch Arm

F.

Set Screw

J. Cross Pin

C.

Plunger Link

G.

Clutch Shaft

K. Driver

D.

Clutch Arm

H.

Camshaft Shaft

L. Counter Shaft

Fig, 6-1-77A, F60160. Clutch arm removal and clutch

adjustment

Gauge Damping And Mounting

One area in which increased compatibility can be

realized between factory and field test stands, is fuel

pressure gauge hand stability. Erratic action of gauge

hand is a result of'

one or both of the following factors:

1. Hydraulic pulsations being carried into the gauge

because of damping valve not being properly

adjusted. With the adjustable damping valve it

is impossible to insure that all test stands can be

adjusted to the same degree of damping.

2. Mechanical vibration being transmitted into

gauge as a result of one of the following

conditions.

a. Operation of test stand with gauge mounts

broken.

b. Gauge line positioned so it "pulls" or "pushes" on

gauge and in effect becomes a rigid member

between gauge and test stand frame.