TRUCK SERVICE MANUAL

FUEL SYSTEM

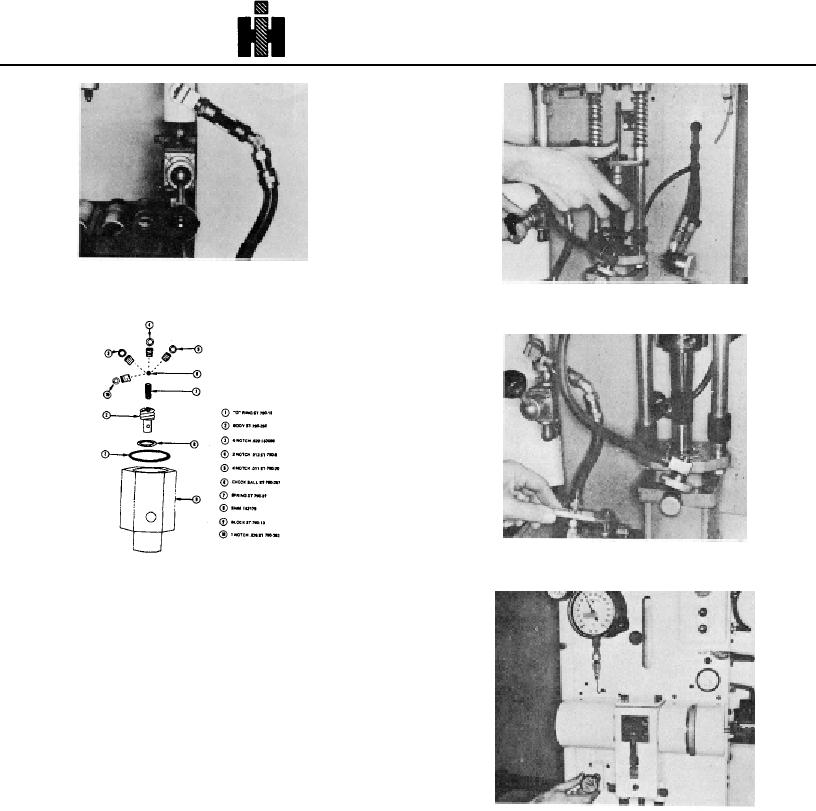

Fig. 6-1-83, F60133. Hydraulic fluid sight glass

Fig. 6-1-85, F60135. Position assembly

Fig. 6-1-86, F60136. Close hydraulic valve

Fig. 6-1-84, F60134. Injector seat restrictor orifice

11. the air valve and as the injector goes in clamped

position make sure the link is properly aligned

and engaged. Fig. 6185.

12. Check the air pressure gauge at top of hydraulic

reservoir as originally established with the load

test cell. Close the hydraulic valve to lock the

injector in clamped position. Connect the inlet

and drain connectors to the injector. Fig. 6186.

Caution:

To avoid damage to master injector, do not use ST708

Burnishing Tool when setting up test stand.

13. Start the test stand motor.

Fig. 6-1-87, F60137. Adjust to 120 psi

Note: Test oil must be a minimum of 90 deg. F [32 deg.

C] . If temperature is not up to 90 deg. F [32 deg. C]

test stand must be warmed up on a standard injector, not

Pressure (120 psi [827 kPa] ) must be maintained at all

the master injector. If temperature exceeds 95 deg. F

times during calibration and testing.

[35 deg. C], increase cold water flow. If temperature

exceeds 135 deg. F [57 deg. C] drain and replace with

new test oil.

14. Adjust the fuel pressure by turning the regulator

knob until the pressure gauge shows 120 psi

[827 kPa] . If this pressure cannot be achieved,

the trouble probably is due to a sticking air

regulator, or to a worn gear pump. Fig. 6-1-87.

475