TRUCK SERVICE MANUAL

FUEL SYSTEM

Note: Delivery for injector with approximate strokes of

800 in Table 6115 is established by setting ST790 Stand

with master injector, then turning back the counter by

20%. For example, if test stand counter was read at

1050 with master, the injectors to be tested would be run

at 840 counter strokes.

2. Lubricate inside of Service Tool 3375086,

ST1058 or Body with test oil so Injector "0" rings

will slide into adapter without damage to "0"

rings.

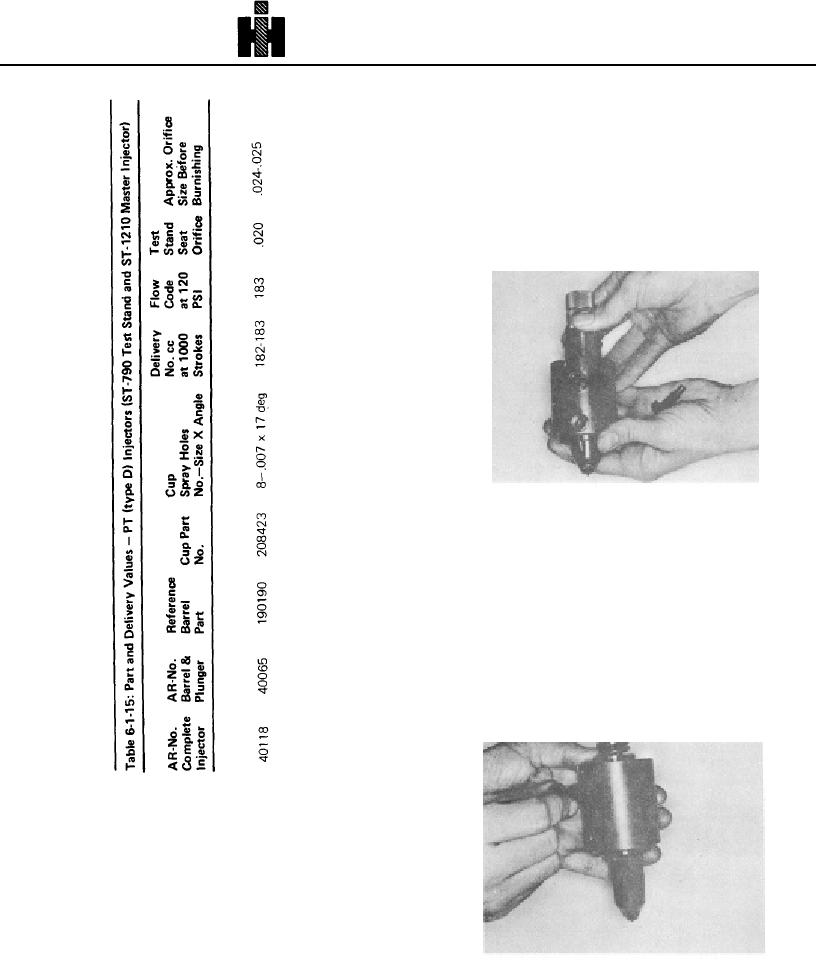

Fig. 6-1-109, F60203. Center injector inlet in ST1058

inlet hole

3. Seat injector in body so injector Inlet aligns with

body inlet hole. Fig. 61109. Tighten locating

screw. Fig. 61110.

4. Remove spring and plunger from injector

adapter. Leave spring off and install plunger into

adapter.

5. Perform ball valve seating check before

calibrating injector.

a. Attach test stand inlet pressure line to drain

connection of Service Tool 3375086, ST1058

Body.

Fig. 6-1-110, F60212. Tighten ST1058 locating screw

478