TRUCK SERVICE MANUAL

FUEL SYSTEM

Note: All tests on test stand are performed without a

b. Hold injector plunger down against its seat in

screen on injector.

injector cup with injector in a vertical position.

13. Assemble ST-708 Burnishing Tool into test stand

Assembly may be held in hand, do not place in

injector inlet connector. Retract the needle by

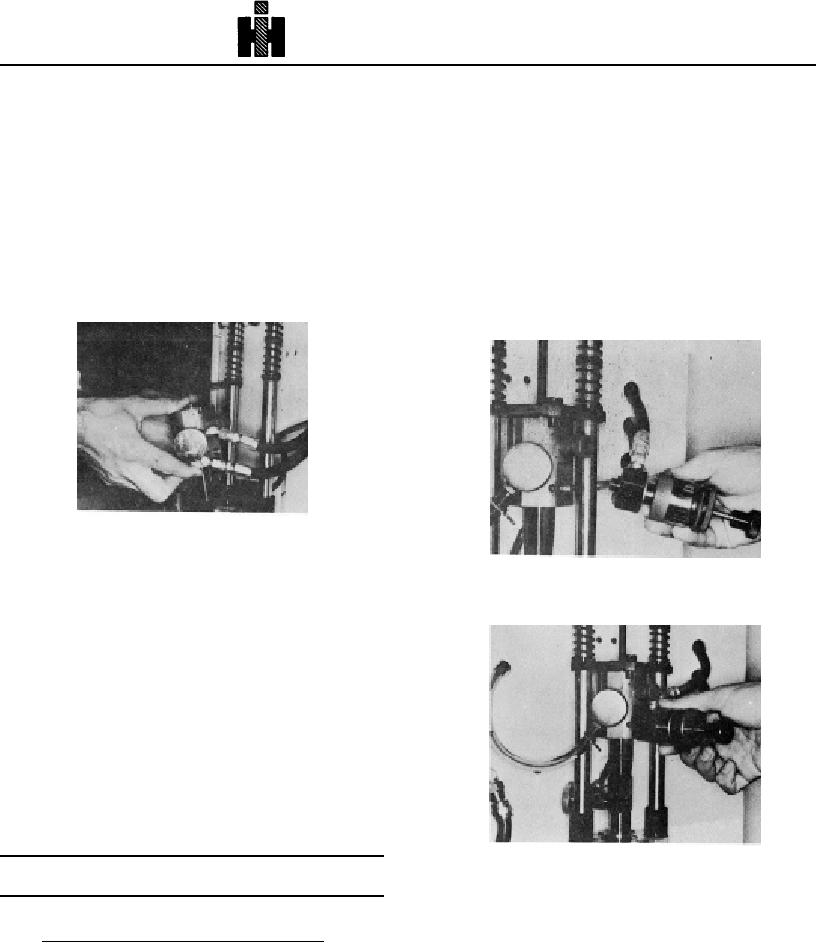

test stand holding device. Fig. 6-1-111.

pulling out small knob. With needle retracted

Note: Be sure ST-708-1 Needle is retracted.

ST-708 tool may be left in connector during all

c. Turn on test stand, and adjust pressure to 150

test operations.

psi [1034 kPa .

Note: Injector delivery is adjusted by burnishing the inlet

d. Check orifice plug inlet opening of Service Tool

orifice plug with ST-708 instead of changing the plug.

3375086, ST-1058 Body for leakage past ball

The replaceable needle point, ST-708-1, is the

valve.

burnishing member.

Note: Make sure plunger is seated in cup.

14. Install connector and ST-708 tool into Service

e. If leakage is observed, the ball must be

Tool 3375086, ST-1058 Body inlet by screwing in

replaced. Slight seepage is not harmful.

the large knob section. Fig. 6-1-112.

Fig. 6-1-111, F60213. Check leakage at inlet port

6. Install injector in Service Tool 3375086, ST-1058

Fig. 6-1-112, F60214. ST-708 installed in inlet

or Body. Disconnect Inlet pressure line from

connection

drain connection of body. Remove injector

plunger.

7. Seat injector so injector inlet aligns with body

inlet hole after injector adapter is located in

sleeve.

8. The location screw must seat in hole of adapter.

9. Check to be sure injector inlet is centered in

body inlet hole to prevent breaking ST7081

Burnishing Tool points when installed later.

10. Install spring and plunger into injector.

11. Assembly retainer plate over injector with pins

engaging in body.

12. Position injector in test stand with correct

adapter link. See Table 611.8.

Table 6-1-18: ST-790 Test Stand Link Data PT (type

Fig. 6-1-113, F60215. Assemble ST-70a tool to pot

D)

Length

Inch [mm]

Link Marking

6.5 [165]

ST-790-331

479