TRUCK SERVICE MANUAL

Fig. 5 1-8, F5103. 50 cycle motor brush location to

reverse motor

6. The last six spaces on the second line give the

calibration card number and suffix letter. 0101-11521-

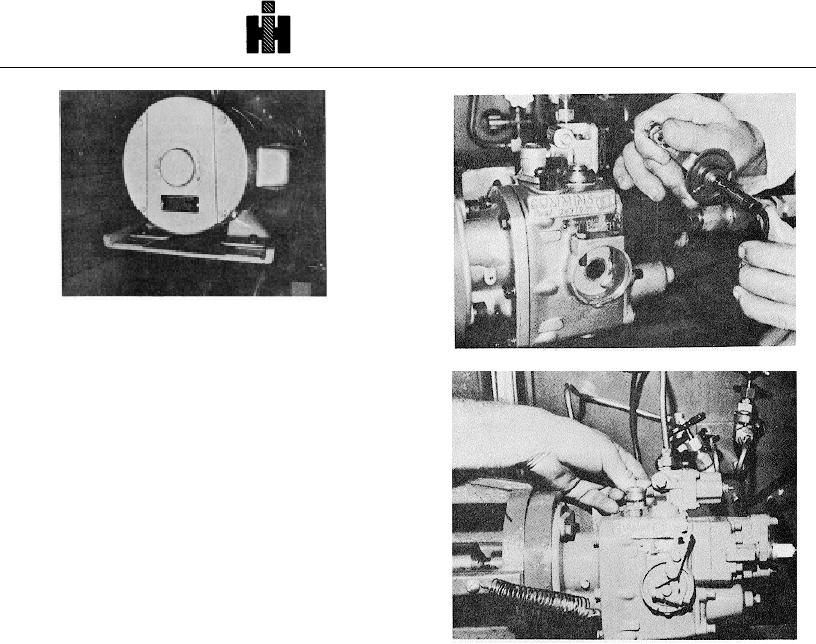

Fig. 5-1-11, F5104. Shim throttle restriction plunger

846067 L-BM-704862433C.

7. On fuel pumps with torque modification device, a

second nameplate will show regulator code number and

setting in thousandths of an inch.

Note: On Woodward governor pumps, the BM or AR

number will be for fuel pump only.

Run-ln

1. Remove throttle lever cover snap ring and pull shaft

from housing. Inspect restriction plunger to b(e certain

hole is shimmed completely open. Fig. 5-1-11. This is

not necessary if calibration is being checked as a trouble

shooting step. Replace shaft.

2. Move and hold throttle control lever to full fuel

Fig. 5-1-12, F5171. Opening shut-down valve

position, it may be necessary to adjust the throttle screws

to Insure that the fuel port in the throttle is fully open and

Calibration Procedure Flow Meter Method

indexed with the fuel passage in the fuel passage in the

Set Governor Cut-Off Speed

body. It is not necessary to adjust the throttle screw If

Standard Automotive Governor

the calibration is merely being checked as a trouble-

1. Close idle, leakage and pressure valves. Open flow

shooting step.

control or needle valve wide open.

3. Open completely the fuel pump shut-down valve, by

2. Increase pump speed to engine rated speed.

turning knob clockwise (manual button, Fig. 5-1-12) and

flow control valve. Open throttle, wide open positron,

3. Adjust vacuum valve in fuel pump suction line to

(secure open with a spring) start and run pump at 500

obtain 8 inch [203 mm] Hg. on vacuum gauge. Fig. 5-1-

rpm

14.

4. If pump is newly rebuilt or has been opened, run at

4. If you cannot obtain 8 inch [20.8 check of vacuum,

slightly over rated speed for five minutes to flush, allow

check for restriction min test stand filter or fuel supply

bearings to seat and to purge all air from the system.

line.

5. Before starting calibration, check pump fuel flow in

5. Close the fuel manifold orifice valve or main flow

the flow-meter for air. If air is present, correct leak

control needle valve until the flow-meter shows the flow

before continuing test.

specified under "Flow-Meter" in the calibration data (425

6. The test oil or fuel temperature must be 90 deg. to

Ib/hr on an NH-22Q pump). There must be no air visible

100 deg. F [32 deg. to 38 deg. C].

in the flow-meter. Fig. 5-1-15. Disregard change in

vacuum readings at this setting.

7. Set gear pump at 8 inch [203 mm] Hg.

vacuum

during run-in.

525