TRUCK SERVICE MANUAL

STEERING

4. Check system over for external leakage.

PRESSURE CHECKING THE POWER

Leakage is usually indicated by an oilwetted

STEERING PUMP SYSTEM

area, oil dripping or oily dirt accumulation. Since

air and fan draft have probably spread leaking

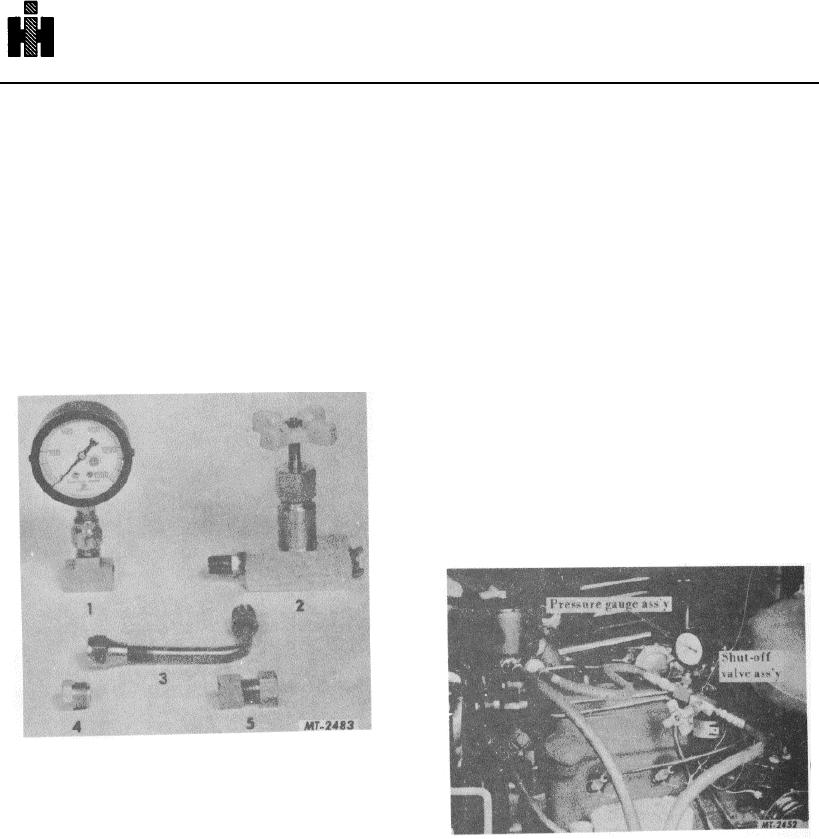

To check the hydraulic system, we use a pressure

oil, clean the entire system off thoroughly, then

gauge and high pressure shutoff valve. Here is the

operate and watch for leakage. Usual points for

specially designed testing equipment. Use standard

leaks are around fittings or along hoses which

hydraulic hose con

.,/ nections with the testing

have burst or split under stress and strain.

equipment.

Leakage can cause the same troubles as a low

oil supply in the reservoir and a "lump" or hard

spot in steering. Air occasionally causes shimmy

The special equipment as shown in Fig. 18 is

too.

designated as SE-1985 and consists of the following:

1.

SE-1985-1

Pressure Gauge

2.

SE-1985-2

Shutoff Valve

D. The third step is to check pump pressure.

90 Angle Tube Line Assembly

3.

SE-1985-3

4.

SE-1985-7

Flared Plug

5.

SE-1985-8

Inverted Flared Cap

First check the entire system for pressure, then the

components to isolate a malfunction.

1. Insert the pressure gauge and shutoff valve

between the pump and control valve, as shown

in Fig. 19.

Fig. 18 Special Testing Equipment

Fig. 19 Pressure Gauge Installed in System

632