TM 5-3805-274-13&P

0034

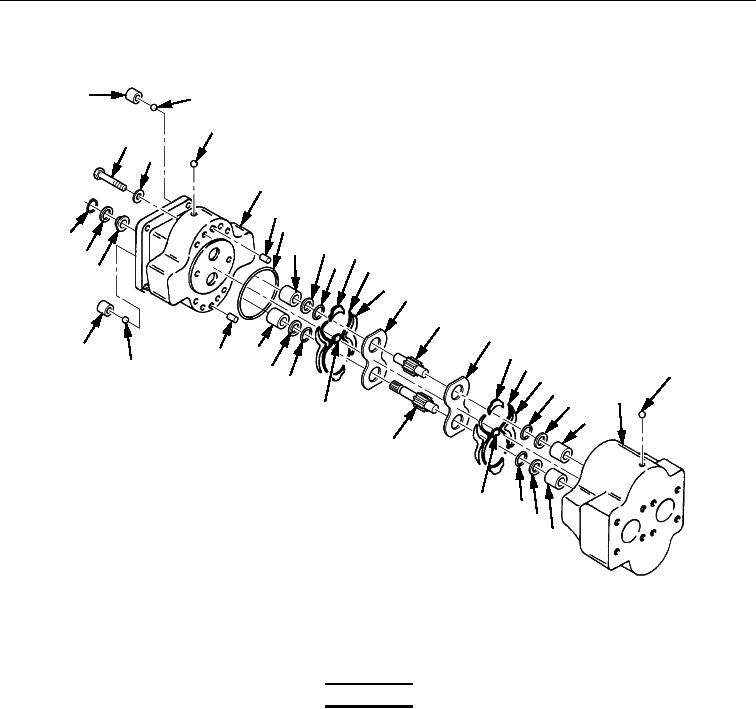

DISASSEMBLY - CONTINUED

1

2

3

30

31

4

5

6

29

8

7

10

28

9

11

27

12

13

14

15

1

16

7

5

17

2

23

8

18

9

19

22

20

26

21

25

24

19

20

21

Figure 1. Hydraulic Pump Disassembly.

END OF TASK

CLEANING AND INSPECTION

WARNING

Compressed air used for cleaning must not exceed 30 psi (207 kPa).

Use only with effective chip guarding and personal protective

equipment (goggles/faceshield, gloves, etc.). Failure to comply may

result in injury to personnel. Seek medical attention in the event of an

injury.

NOTE

Wash all parts thoroughly with clean solvent and blow dry. This

should remove any foreign matter trapped in the pump.

1. Visually inspect all parts. Gear track is inside pump body (Figure 1, Item 22). Measure depth of gear

track. If groove is deeper than 0.0050 in. (0.013 cm), body should be rejected. If track is less than

0.005 in. (0.013 cm), body may be reassembled provided it is not cracked or damaged.

2. Examine top pressure plate (Figure 1, Item 13) and bottom pressure plate (Figure 1, Item 15). If gear

track or groove is deeper than 0.005 in. (0.013 cm), replace plate.

3. Gear journals should be measured within 0.38 in. (0.96 cm) of gear. Measure diameter of journals where

shaft has run in bearings. Gears should be rejected if there is more than 0.001 in. (0.0025 cm) variation

in two measurements.