TRUCK SERVICE MANUAL

BRAKES-AIR

ASSEMBLE

A. Clean all parts thoroughly and inspect. Check

angled faces of wedge to see that they are free from

pits or marks. If "E" washer type lock is used,

inspect wedge shaft lock groove to see that it is

sharp and clean. Inspect roller retainer cage to

make sure it will contain rollers properly and inspect

the spring for marks that would cause breakage.

Replace parts if necessary.

B.

Insert wedge shaft into roller retainer cage so

angled faces of the wedge head are exposed.

These tabs serve to align the wedge assembly as it is

installed into the plunger housing by engaging grooves in

the wedge bore. If the plunger housing is not equipped

with such grooves, remove the tabs at the breakoff

marks and file the O.D. of the retainer smooth.

E

Install wedge spring over wedge shaft, large coil

diameter first. Add spring washer and compress

spring by hand far enough to expose cotter key hole

C.

Insert a thin bladed screwdriver between flat of the

or "E" lock groove and install lock (cotter key or "E"

wedge head and roller retainer cage. Spread cage

washer).

open just far enough to insert roller (journal hub into

cage slot). Tip roller into cage and position other

F. Install the wedge assembly into the plunger housing.

journal hub into slot of retainer. Install other roller in

Check for correct roller-plunger engagement by (1)

same manner and remove screwdriver. DO NOT

pushing on wedge rod by hand while checking for

force rollers thru ends of the cage slots.

plunger and shoe lift, and (2) measuring the standout

of the wedge rod from the end of the threaded

D. Install spring retainer over wedge shaft and position

housing bore. When properly assembled, the wedge

centrally over cage and roller assembly. Install rub-

standout is 2 1/4

ber boot when used.

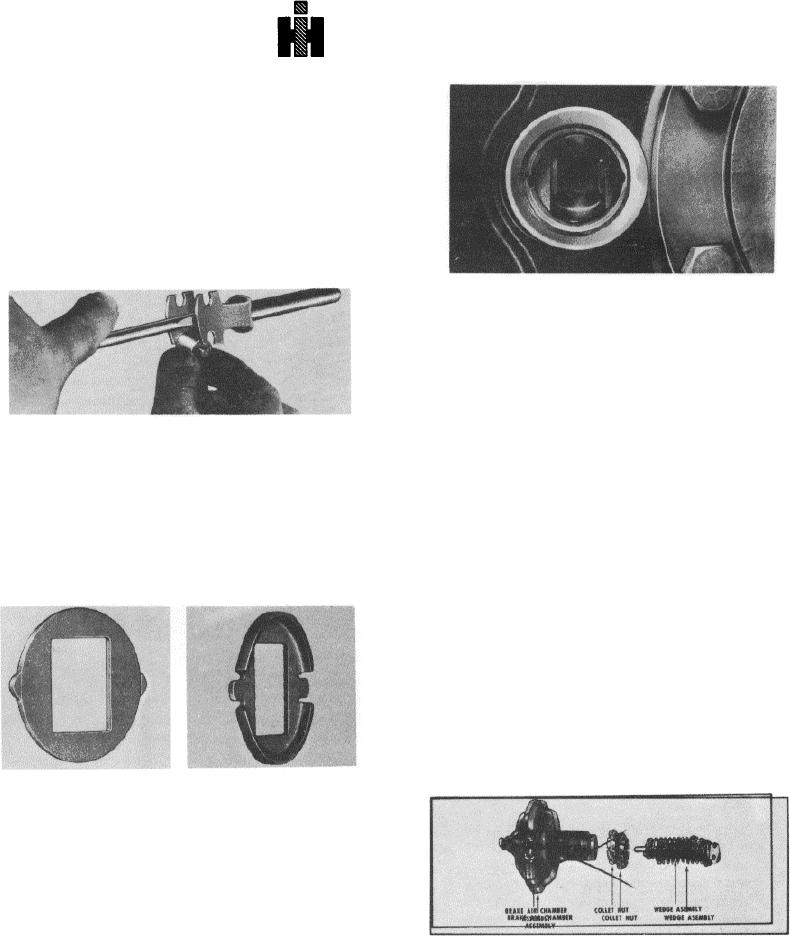

INSTALLING POWER UNIT ONTO

BRAKE ASSEMBLY

A. Check position of the wedge in plunger housing to

make certain wedge assembly is properly seated.

Be sure to replace automatic adjusting identification

ring (if used) on power unit tube. Thread spanner

nut or collet nut onto power unit tube and install

spanner nut retainer if used. Apply a non-hardening

1 1/2" ASSEMBLY

1 3/4" ASSEMBLY

sealer to the first three threads of the chamber tube.

NOTE: Current production and service replacement use

a spring retainer that has two tabs or protrusions on the

O.D.

This is the correct position of the collet nut when used

with current brake spider having a conical counterbore.

207