TRUCK SERVICE MANUAL

BRAKES-AIR

GENERAL MAINTENANCE

SERVICING POWER UNITS

BRAKE ADJUSTMENT

AIR CHAMBER DIAPHRAGM

A. Manual Adjusters.

1.

Jack or hoist wheels free of ground.

The following procedures are used to replace the

2.

Remove dust cover from adjusting slot two

diaphragm and boot with the non-pressure housing on /

places on each brake.

the brake assembly.

On RD type brakes the adjusting slots are below

A. Refer to PARKING BRAKE SECTION for removal of

the forward and above the rear power unit.

spring brake air chambers.

If star-wheel adjusting bolts are not found at

these positions, the brake had been assembled

B. Remove air lines and tag emergency line.

on the wrong side of the vehicle.

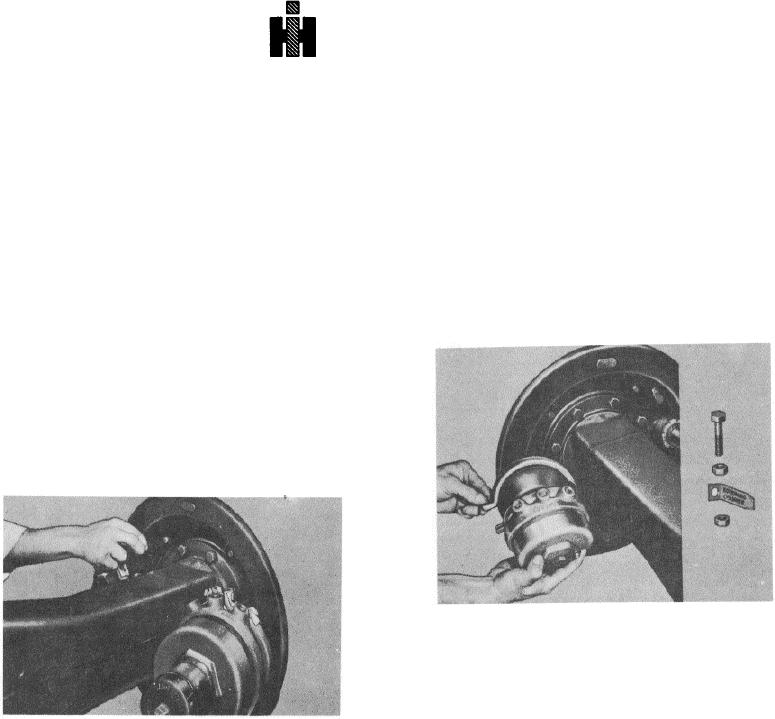

C. Remove clamp ring nuts, bolt

3.

Adjusting bolts have right hand threads. With an

adjusting spoon, turn the star-wheel until a

heavy drum drag is developed. Then back off

the bolt to a very light drag on the drum.

Repeat for other shoe on the brake. Replace

dust covers in adjusting slots. Repeat for other

brakes.

NOTE: Recommended adjusting spoons, are Snap-On-

Blue-Point S-9523, Wizard 4-H-2530 and Proto 2006.

D. Spread the clamp ring. Hold the diaphragm on the

non-pressure half and remove the pressure half

E.

Carefully remove the diaphragm while holding

diaphragm plate against the wedge rod. This will prevent

the wedge assembly from coming out of engagement

with the plungers.

B. Automatic Adjusters

1

Check drum to lining clearance with feeler gage.

NOTE: If wedge assembly backs out of plunger anytime

If the clearance is more than .060", adjust

during this entire procedure, remove non-pressure

brake manually (same as above) and schedule

housing

from

brake

to

replace

diaphragm.

the

vehicle

for

brake

service.

204