TRUCK SERVICE MANUAL

BRAKES-AIR

F.

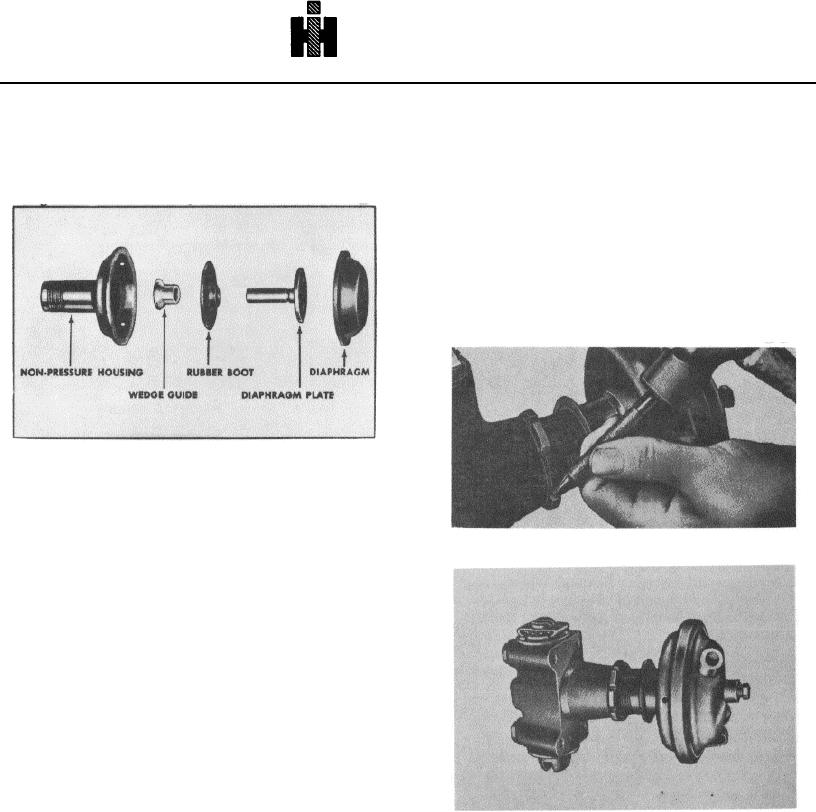

Continue to hold plate and inspect boot. If boot is

torn or not attached to housing, strip old boot free

from housing and carefully re- move plate assembly

REMOVING POWER UNIT

off wedge rod and out of non-pressure housing

FROM BRAKE ASSEMBLY.

tube. (Boot and wedge guide will remain on plate

push rod.)

A.

Remove brake lines and tag emergency line.

B

Determine the type of power unit used, bottoming or

adjusting type. (Bottoming air chambers have an

identification tag fastened to the clamp ring bolt

C.

If adjusting type unit is used, carefully mark the

position of the assembly on the first exposed thread

on the housing tube with a scribe or punch and

hammer to aid reassembly.

G.

Remove wedge guide and old boot from push rod.

Inspect guide for wear and replace if necessary.

H.

Install new boot on diaphragm plate push rod and

press wedge guide all the way onto end of push rod.

D.

Using a drift or other blunt tool and hammer,

J.

Clean non-pressure housing with cement thinner or

loosen the collect nut.

similar material in area where boot is to be

cemented.

K

Apply cement to housing around tube end. Position

the plate-push rod assembly into tube. Carefully

engage wedge rod so as to not pull it out of

plungers.

L.

While holding plate against wedge, press boot into

position for cementing.

M.

Install new diaphragm over plate and onto

nonpressure housing while pushing plate against

wedge. Assemble pressure half and clamp ring in

reverse manner of disassembly.

NOTE

On welded on spider mounted brakes with open ends the

N.

Connect air lines to proper chamber ports. Make a

entire actuation system can be taken off at this time if

full-pressure brake application and check for air

desired as one assembly by removing four spider to

leaks.

Road test for brake performance.

plunger housing capscrews. However, the hub and drum

and dust shield will have to be taken off before removing

the actuation system.

205