TRUCK SERVICE MANUAL

ENGINE

2. Use light finger pressure at rocker lever contact

surface (1) to hold crosshead in contact with valve stem

(2) (without adjusting screw).

3. Turn down crosshead adjusting screw until it touches

valve stem (3).

4. With new crossheads and guides,-advance setscrew

an additional one-third of one hex (20 deg.) to straighten

stem on its guide (5) and compensate for slack in

threads. With worn crossheads and guides, it may be

necessary to advance screw as much as 30 deg. to

straighten stem on Its guide.

5. Using ST-669 Torque Wrench Adapter, tighten

locknuts to 22 to 26 ft-lbs [30 to 35 Nml. If ST-669 is

not available, hold screws with screwdriver and tighten

locknuts to 25 to 30 ft-lbs [34 to 41 Nm]

Fig. 2-53 (N-11466)

6. Check clearance (6) between crosshead and valve

Table 2-14: Injector Adjustment (Oil Temperature)

spring retainer with wire gauge. There must be a

minimum of 0.025 inch [0.64 mm] clearance at this point.

Cold Set

Hot Set

Valve Adjustment

Cast Iron Rocker Housing

The same engine position used in adjusting injectors is

48 inch-lb

72 inch-lb

used for setting intake and exhaust valves.

[5.4 N m]

[8.1 Nm]

Aluminum Rocker Housing

1. While adjusting valves, make sure that the

72 Inch-lb

72 inch-lb

compression release, on those engines so equipped, is

18.1 No m]

[8.1 Nm]

in running position.

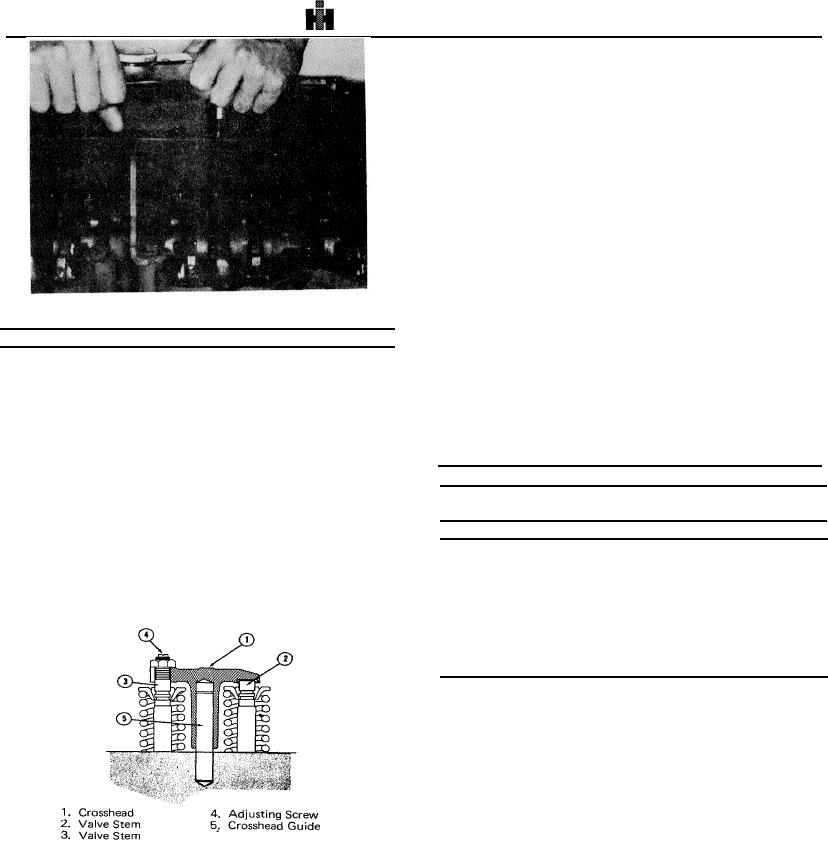

Crosshead Adjustment

Table 2-15: Valve Clearance - Inch [mm]

Crossheads are used to operate two valves with one

rocker lever. The crosshead adjustment is provided to

Intake Valves

Exhaust, Valves

assure equal operation of each pair of valves.

The crosshead adjustment changes as a result of valve

Cold Set

Hot Set

Cold Set

Hot Set

seat wear during engine operation.

Make sure

Aluminum Rocker Housing

crossheads are adjusted before adjusting valve rocker

0.014

0.014

0.027

0.027

1. Loosen valve crosshead adjusting screw locknut and

[0.36]

[0.36]

[0.69]

[0.69]

back off screw (4, Fig. 2-54) one turn.

Cast Iron Rocker Housing

0.016

0.014

0.029

0.027

(0.411

[0.361

(0.74]

[0.691

2.

Loosen locknut and back off the

adjusting screw. Insert feeler gauge between rocker

lever and crosshead. Turn the screw down until the lever

just touches the gauge and lock the adjusting screw in

this position with the locknut. Fig. 2-55. Tighten locknut

to 40 to 45 ft-lbs [54 to 61 No m] torque. When using

ST-669 torque to 30 to 35 ft-lbs [41 to 47 NM].

3. Always make final valve adjustment at stabilized

engine lubricating oil temperature. See Table 2-15 for

appropriate valve clearances.

Fig. 2-54,(N21461) Valve crosshead.

299