TRUCK SERVICE MANUAL

ENGINE

6. Variations in governor characteristics make small

Note: "No air" pressures are given in Fuel Pump

difference in maximum governed speed between

Calibration Manual. Check with a Cummins Distributor.

different engines.

Such variations are of small

importance In most applications.

13. Always make the above checks on a hot engine.

Note:

Injectors must be adjusted to proper

Check Aneroid Adjustment

specifications before fuel manifold pressure readings.

Normally, no adjustment of the aneroid is required,

however, if smoke is evident and all other engine

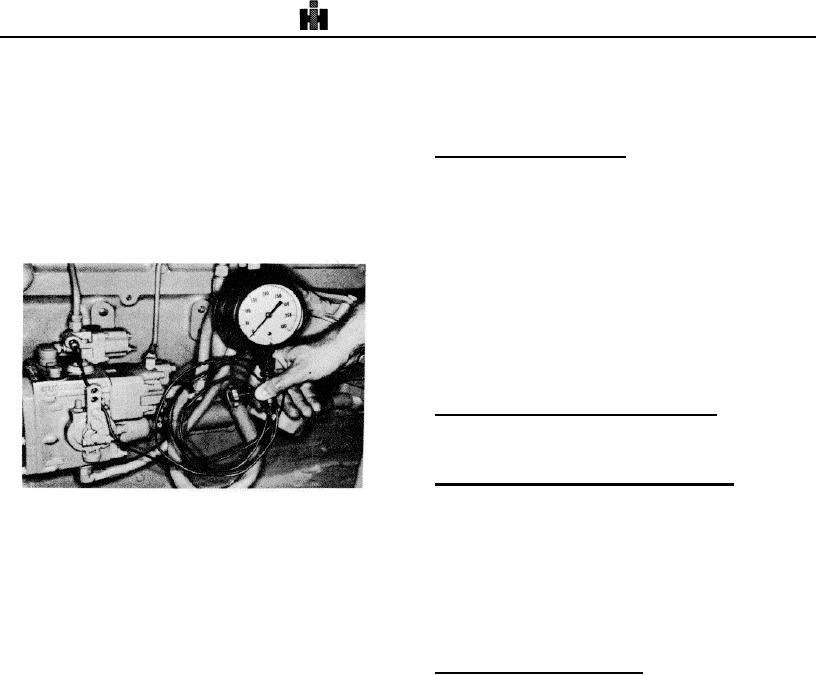

7. Check maximum fuel manifold pressure with ST-

adjustments have been checked, back out adjusting

435. Fig. 2-64. Remove 1/8 inch pipe plug from side of

screw (4, Fig. 2-65). If screw must be backed out until

fuel shut-off valve on top of fuel pump. Connect the

acceleration is slow, have unit checked by a Cummins

gauge line in pipe plug hole.

Distributor.

Note: If smoke is excessive after 15 seconds of full

throttle operation, aneroid is not at fault, have fuel

system and turbocharger checked.

If, during Fuel Manifold Pressure Check, it is determined

that aneroid bellows should be replaced,

Check Turbocharger Bearing Clearance

Check bearing clearances every "C" Check; refer to "D"

Check.

Change Aneroid Oil And Replace Breather

At each "C" Check, remove fill plug and drain plug ,

Fig. 2-64, (N11966) Checking fuel manifold pressure

allow aneroid to drain. Replace drain plug , fill aneroid

with ST-435

with clean engine lubricating oil. Replace fill plug.

8. Remove linkage from the throttle lever. This will

Remove and replace aneroid breather Tighten breather

allow throttle to be operated by hand.

to 10 to 13 ft-lbs [15 to 18 No m] torque.

Caution:

On turbocharged engines with aneroids,

'D" MAINTENANCE CHECKS

temporarily disconnect aneroid, inlet line and plug hole,

At each "D" Maintenance Check, perform all "A", "B" and

to reach maximum fuel pressure during the short

"C" Checks in addition to those following.

acceleration period.

Clean And Calibrate Injectors

9. Start the engine. Run long enough to purge air from

Clean and calibrate injectors regularly to prevent

the pump. Loosen the gauge end of pressure line and

restriction of fuel delivery to combustion chambers. To

bleed air from line.

clean and calibrate injectors refer to FUEL SYSTEM,

Injectors, Calibration Instructions.

10. Watch gauge closely and snap throttle fully open.

The gauge hand will hit a maximum value, then

Replace Fuel Pump Screen And Magnet

immediately drop back as the governor takes control.

PT (type G) Fuel Pump

1. Loosen and remove cap, remove "O" ring and

11. Compare the maximum value with previous readings

spring.

taken to determine if fuel readings are satisfactory.

2. Lift out filter screen assembly. Discard screen

Normally this check is only taken if there is a suspected

assembly.

loss of power.

3. Install new filter screen assembly in fuel pump with

hole down, position spring on top of filter screen

12. Remove plug and reconnect aneroid to fuel pump,

assembly.

remove air line from intake manifold to aneroid and

4. Replace cap and "O" ring; tighten to 8 to 12 ft-lbs [11

check "no air" pressure.

to 16 Nm] torque.

301