ENGINE

TRUCK SERVICE MANUAL

2. Bar engine in direction of rotation until a valve set

mark (1, Fig. 2-52) aligns with the boss (2) on the gear

case cover. Example: A or "1-6 VS". This location is

marked with a notch in the drive pulley. Note: Fig. 2-52

illustrates 3-4 "VS" valve set mark,

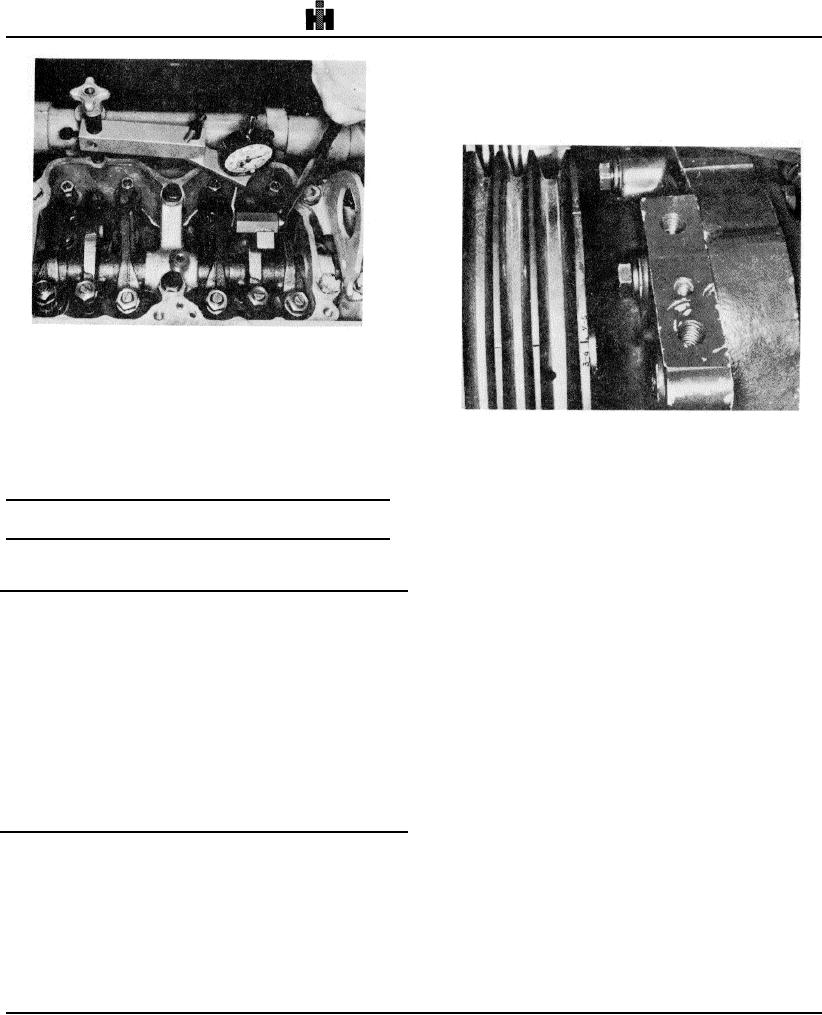

Fig. 2-51, (N114237) Bottoming injector plunger in cup

7. Actuate injector plunger several times as a check of

adjustment. Remove dial indicator assembly.

8. Adjust valves on appropriate cylinder as determined

Fig. 2-52, (N114220) Valve set timing marks

in Step 1 and Tables 2-11 and 2-12. Tighten locknuts

same as injector locknut.

3. Check the valve rocker levers on the two cylinders

9 Continue to adjust remaining cylinders. See Table 2-

aligned as indicated on pulley (example: 1 and 6

11.

cylinders for A or "1-6 VS"). On one cylinder of the pair,

both rocker levers will be free and valves closed, this is

Table 2-12: Adjustment Limits Using Dial Indicator

cylinder to be adjusted.

Method Inch [mm]

4. Adjust injector plunger first, then crossheads and

Oil

Injector

Valve Clearance

valves to clearances indicated in the following

Plunger

paragraphs.

Temp

Travel

Intake

5. Engine Firing Order is 1-5-3-6-2-4.

Aluminum Rocker Housing

6. Continue to bar engine to next "VS" marks and

adjust each cylinder in firing order.

Cold

0.170 + 0.001

0.011

0.023

Note: Only one cylinder is aligned at each mark. Two

(4.32 + 0.03]

[0.28]

[0.58]

complete revolutions of the crankshaft are required to

Hot

0.170 + 0.001

0.008

0.023

adjust all cylinders.

[4.32 + 0.03]

[0.20]

[0.58]

Cast Iron Rocker Housing

Injector Plunger Adjustment

The injector plungers must be adjusted with an Inch-

pound torque wrench to a definite torque setting. A

Cold

0.175 + 0.001

0.011

0.023

torque wrench with a screwdriver adapter can be used

[4.45 + 0.031

[0.28]

[0.58]

for this adjustment. See Fig. 2-53.

Hot

0.175+ 0.001

0.008

0.023

1. Turn adjusting screw down until plunger contacts cup

[4.45 + 0.03]

[0.20]

[0.58]

and advance an additional 15 degrees to squeeze oil

from cup.

Adjust Injectors And Valves NH, NT (Torque Method)

2. Loosen adjusting screw one turn; then, using a

torque wrench calibrated in inch-pounds and a

Timing Mark Alignment

screwdriver adapter, tighten' the adjusting screw to

1. Loosen the injector rocker lever adjusting nut on all

values shown in Table 2-14 and tighten the locknut to 40

cylinders.

This will aid In distinguishing between

to 45 ft-lb [54 to 61 Nm] torque. If ST-669 Torque

cylinders adjusted and not adjusted.

Wrench Adapter is used, torque to 30 to 35 ft-lb [41 to 47

Nm.

298