TRUCK SERVICE MANUAL

ENGINE

Unit removal is a simple operation, time and labor will be

Engine Disassembly Group 0

saved if the necessary steps are followed. A few

precautions are included that will help prevent accidents

and/or damage to the parts.

The following service tools or tools of equal quality are

considered necessary to disassemble the 855 C.I.D.

identify mounting components, as removed, for mounting

(Cubic Inch Displacement) Series Cummins Diesel

location. Place parts and units (except electrical parts)

Engines.

on a rack or cart for cleaning. Discard gaskets and

lockplates.

Service Tools (Or Equivalent) Required

Engine Serial Number Plate

Service

Tool

Engine serial number plate is located on the gear case

Tool Number

Name

mounting flange. Always refer to serial number and

model designation when ordering parts or assemblies.

ST-125

Lifting Fixture

ST548

Engine Rebuild Stand

ST-805

Engine Stand Adapter

Note:

Non-certified engine serial dataplate, applies to current

Desirable (Or Equivalent) Service Tools

non-certified engines. Certified engine serial dataplate

applies to engines conforming to the Federal (U.S.A )

ST-163

Engine Support

Clean Air Act. Engine serial dataplate may not be

ST-647

Puller (Pulley)

changed without consent and approval of Cummins

ST-845

Fan Hub Wrench

Engine Company, Inc.

ST-887

Crankshaft Flange Puller

ST-893

Fan Hub Wrench

DRAIN WATER AND OIL

ST-1147

Injector Removal Tool

Drain complete system of lubricating oil, fuel and water.

ST-1178

Main Bearing Cap Puller

Bleed compressed air system, if used.

ST-1201

Liner Puller Bridge

ST-1202

Liner Puller Assembly

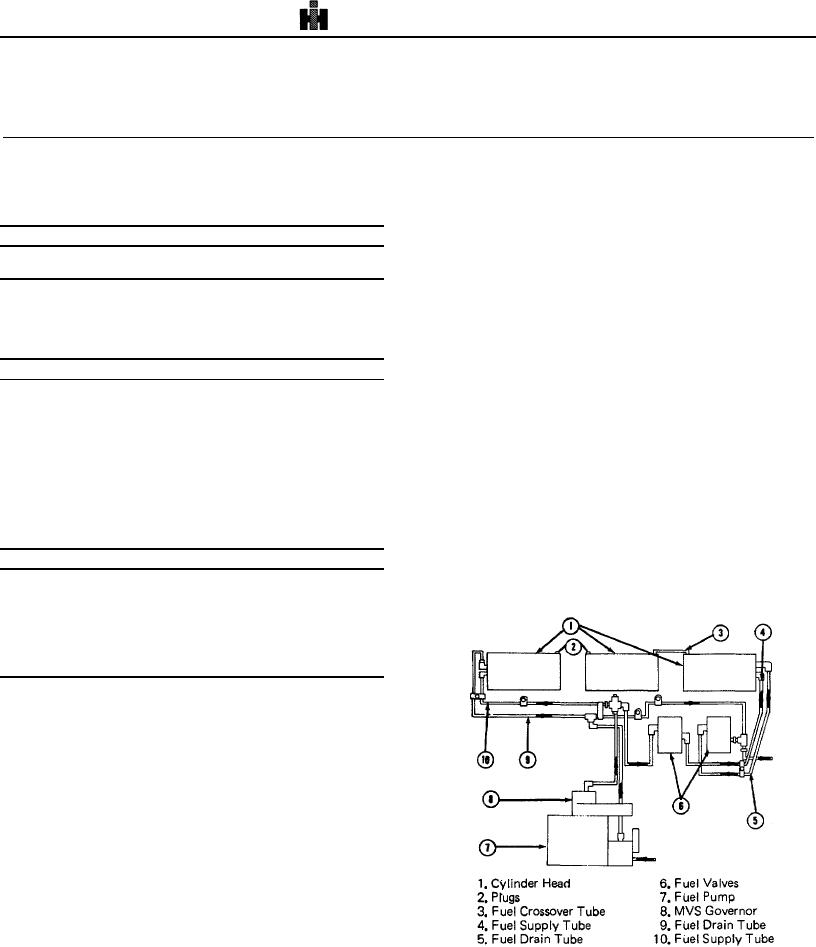

Note: Engines used as Duel Diesels will be equipped

Standard Tools - Obtain Locally

with two sets of fuel lines and additional fuel control

valves so four cylinders can be used for compressor

Hoist (Power or Chain)

pumping. Fig. 0-2

Steam Cleaner

Cleaning Tank

Rinsing Tank

Impact Wrench

Glass Bead Cleaner

UNIT REMOVAL AND CLEANING

Before disassembly of an engine or any unit used on the

engine, inspection of the over-all condition should be

made. This will furnish a great deal of information

concerning necessary repair.

Inspection of each unit and tagging of electrical wires

and components, bearing shell positions and other parts

identification will help insure correct assembly.

Remove units and parts from cylinder block in a

convenient order by removing mounting hardware, such

as clamps, brackets, capscrews, washers, drive belts,

etc. Mark or

Fig. 0-2, (N11830). Typical fuel line and valve plumbing -

dual diesel.

321