STEERING

TRUCK SERVICE MANUAL

7.

Carefully slide the actuating valve into the piston

so that the slot on the end of the valve is

positioned over the pin.

8.

Position the remaining reversing spring on

shoulder of the valve end.

9.

Reinstall valve adjusting nut, turning it clockwise

into the piston until it is against the spring. Align

the reference marks on the nut and piston. Then

lock nut in place by installing the locking pin. Be

sure pin is below the outside edge of piston.

10.

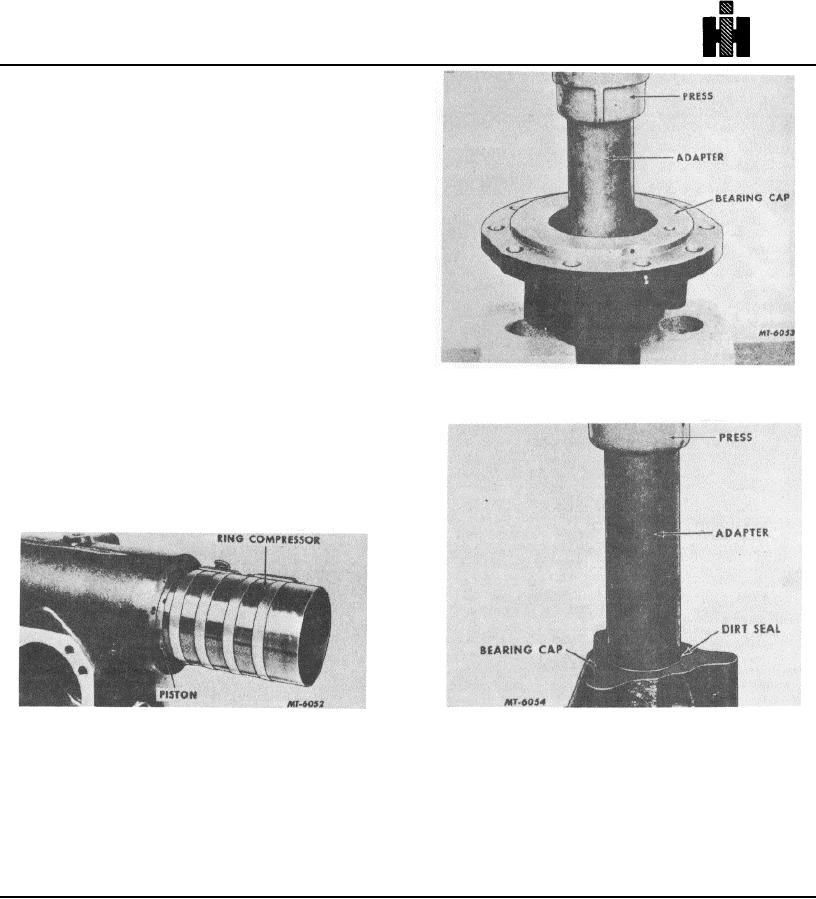

Install piston rings. NOTE: If piston rings are

tapered on one side, install the taper outward to the

piston end. if rings are marked "top" on one side, also

assemble these rings with the marked side outward to

the piston end. Rings which are neither marked nor

tapered are not required to be installed on the piston in

Fig . 31

any special manner.

11.

Install piston assembly using a ring compressor

on each end. Fig. 30 illustrates ring compressor on

second ring. Be sure piston is installed with the

actuating shaft opening facing the bearing cap end.

NOTE: Before installing piston, coat piston and cylinder

walls with oil.

Fig . 32

Fig . 30

12.

Using a new gasket reinstall the cylinder head.

The alignment marks will aid in reinstalling the

head in the correct position. The opening for the

plunger must be in alignment with relief valve in

the piston. Check torque chart for bolt tightening,

643